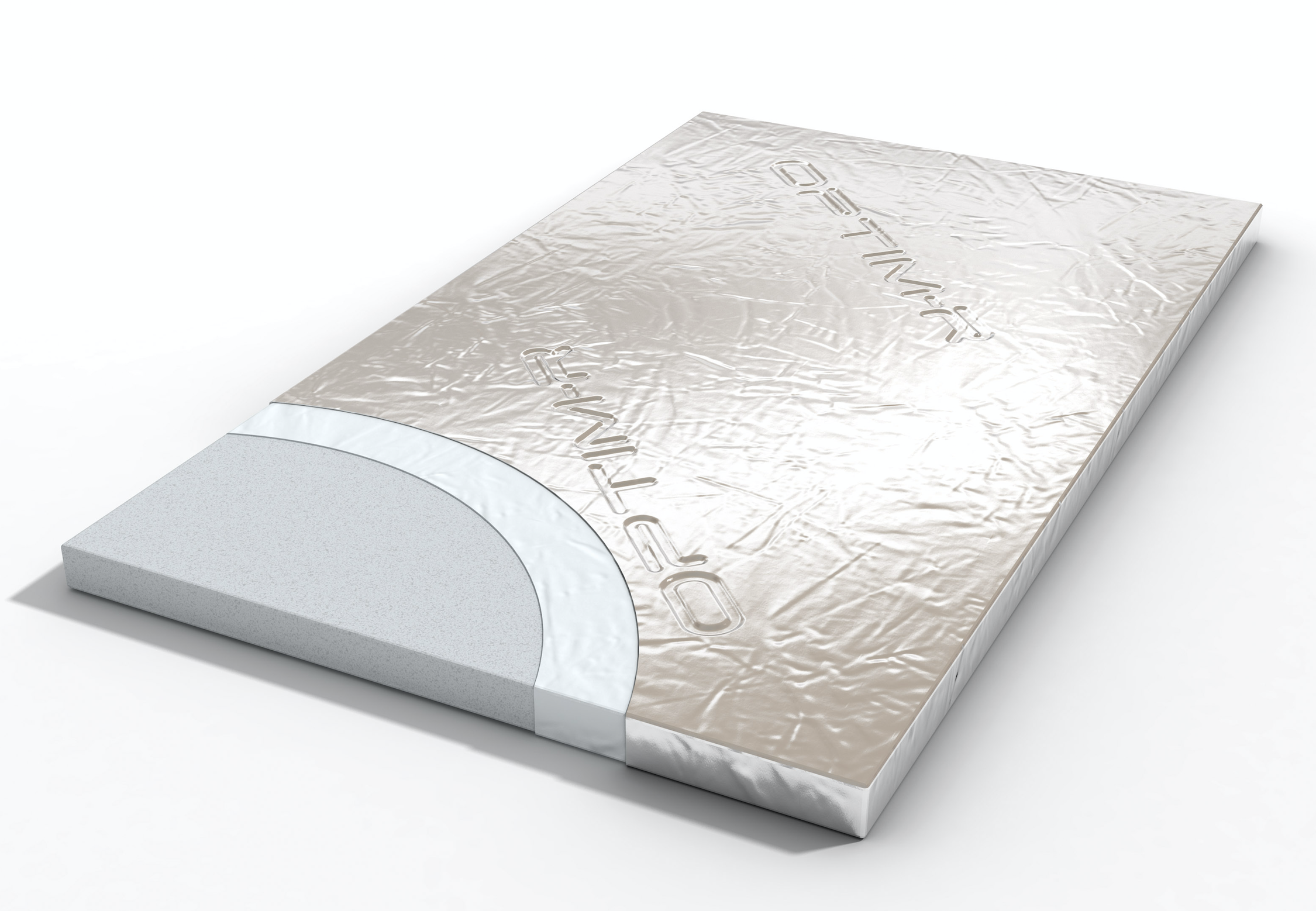

Polyiso Insulation Products Allow Applicators to Manage Adhesive Flash-Off Times

Carlisle SynTec Systems introduces ReadyFlash Technology for SecurShield flat and SecurShield HD polyiso insulation products. ReadyFlash Technology allows applicators to manage adhesive flash-off times by…