There were 4,000 feet of stainless-steel expansion joints on the job, so Trinity had to determine how much the building could move and carefully calculate that into how many joints they could fabricate from each sheet of steel. Each one of the expansion joints had to be completely unique as they crisscrossed the building.

Sixty-six different types and

sizes of precast concrete roof channels, weighing between 225 and 600 pounds, were hoisted by a modified crane. All 30,000 had to be inspected and approved before installation.

The building’s uneven ground made a difference of 2 inches from one end to the other. To offset this size differential, the team added or removed lumber across the project before installing the final sheet metal to make it look picture perfect.

Dealing with Homeland Security onsite demanded meticulous tracking. Each and every crew member had an identity badge and that badge was required to be with them at all times. Every truck delivery had to be scheduled in advance and if a truck arrived that wasn’t on the schedule, it was turned away.

Keeping team morale high throughout the two-year job was integral to a successful project and Cronin is a collaborative leader.

“It was such an undertaking. You don’t walk away with, ‘I did that.’ You walk away with, ‘We did that.’ We’d get all the components working together like a bicycle chain; then, the next day would bring a completely new set of challenges. There was always something to learn, and at the end of the day, everyone contributed.”

Roof Materials

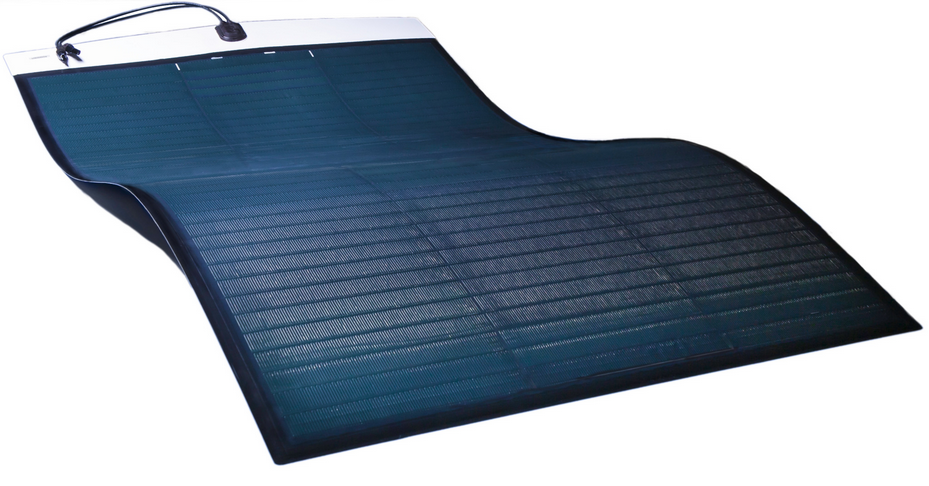

90-mil FB Elvaloy KEE thermoplastic membrane, hot-air welded: Flex

Cellular glass insulation: FoamGlas from Pittsburgh Corning

Impressive Numbers

The James W. Jardine Water Filtration Plant, Chicago,

- Is 10.3 acres in size.

- Dispenses 1 billion gallons of potable water per day to 5 million consumers.

- Features 712,000 board feet of cellular glass insulation.

- Includes 30,000 precast concrete roof channels.

- Used 1,086 rolls, or 448,000 square feet, of thermoplastic membrane.

- Required 112,000 square feet of plywood scaffolding during reroofing.

- Boasts 160 roof drains.

- Required a team of 35 crew members to log 10 miles or more each day just transporting materials on and off the roof.

- Features 20 different designs of expansion joint tie-ins.

Be the first to comment on "Deft Planning and Skillful Moves Play Out on the Reroof of the World’s Largest Water Filtration Plant"