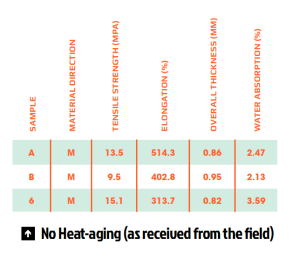

The test results revealed the physical properties of the membrane in the field for 30 years had physical characteristics in aggregate that were within 8 percent of that required for brand-new material, and all exceeded the requirements for aged membrane.

Although the test results proved that in situ 30-year-old EPDM membrane is performing (has good physical characteristics), the question still remained: How long can it last?TESTING PHASE TWO

Thus, the second phase of testing was undertaken. Additional samples were taken from the same five roofs and sent to the National Research Council (NRC) Canada, Ottawa. The protocol this time was to take the 30-year samples and heat-age them for 500 hours at 240 F, which is estimated to be equal to approximately 10 years of in-field exposure. Afterward, a portion of the samples was taken and tested for their physical characteristics. The remaining portion of the sample material was placed back in the oven and heat-aged another 1,000 hours, or 30 years, for an in situ/heat-aged sample of 60 years. Then the physical properties would be tested again.

For comparison, new 45-mil EPDM membranes from a roofing contractor’s warehouse were sent for testing as new material and heat-aged to 10- and 30-year equivalency. The new material was received and measured approximately 47 by 55 inches. Each material was cut into four pieces and placed in an oven at 240 F up to 1,500 hours per ASTM D573.

The overall sheet thickness of the aged in situ EPDM roofing membranes was measured using ASTM D412.

Water-absorption data were obtained using ASTM D471 with samples placed at 70 C for 166 hours.

Tensile strength/ultimate elongation data were obtained using ASTM D412, Die C, and ASTM D751, Grab Method. The specimens were tested in a universal testing machine at a constant crosshead speed of 5 ± 0.2 millimeters per second (12 ± 0.5 inch per minute). The gauge length of the specimens was 75 millimeters, or 3 inches. A minimum of five specimens was tested in machine (MD) and cross (XD) directions except for some samples that had limited material.

RESULTS

THICKNESS, SHEET OVERALL

The overall sheet thickness of the in situ samples ranged from 0.82 – 1.40 millimeters. The minimum requirement is of 1.016 millimeter, or 0.040 inch, as specified in ASTM D4637/4637M for new EPDM membranes. The overall sheet thickness changed after exposure; however, considering they are 30-year samples, this was not unexpected.

PHOTOS: HUTCHINSON DESIGN GROUP LTD.

What are your thoughts on a light molecular weight fluid applied Liquid EPDM membrane system?