With induction welding, the membrane is heat bonded to the top of each plate and there are no penetrations in the membrane. Photo OMG

Over the past ten years, North American roofers have begun to adopt induction welding as a fast, simple and secure way to mechanically attach TPO and PVC membranes. The method also helps create a high-performance roof assembly by eliminating fastener penetrations of the membrane.

For most of its history, induction welding was limited to installations over thermoset insulations such as polyiso or over other rigid insulations with a cover board. But now, a deceptively simple and easy-to-use disc enables roofers to use induction welding over expanded polystyrene (EPS) insulations that don’t have cover boards. The result is faster and more affordable insulation installation and lower fatigue for work crews.

The Induction Welding Method in Brief

A roof fastener manufacturer pioneered induction welding attachment as a way for roofers to streamline TPO and PVC membrane installation, while avoiding membrane penetrations, for a more watertight roof assembly.

In a typical mechanically fastened membrane system, roofers secure the membrane with 2-inch to 3-inch diameter plates on the seams held down by screws that pass through the membrane and insulation layers to the underlying deck. With the induction welding method, each plate becomes a fastening point for the membrane, and the membrane is heat bonded to the top of each plate. With this method, crews screw down the insulation layer as usual, then unroll the membrane over the insulation. They then place a stand-up or handheld induction welding tool on the membrane at each plate location. In less than five seconds, the tool heats the plate under the membrane to about 400 degrees Fahrenheit, bonding the membrane to the plate. Heating is accomplished via electromagnetic induction between the tool and the plate, rather than via direct application of heat (think of an induction cooktop compared to conventional stove heating coils). Induction welding meets the FM 4470 approval standard and is accepted by most membrane manufacturers.

Induction welding typically requires 25 percent to 50 percent fewer fasteners and plates than typical mechanically fastened installations, as well as fewer seams, resulting in both labor and material savings. As the fasteners are spread across the roof in a grid pattern, the resulting assembly enhances resistance to wind uplift and reduces membrane sheet flutter.

EPS Insulations and Induction Welding

Until now, the induction welding process could not be used with EPS insulations that lacked a cover board, as

the 400-degree heated plates caused the insulation to soften and draw back. This resulted in numerous depressions in the roof assembly (at each fastener location), where water could pond.

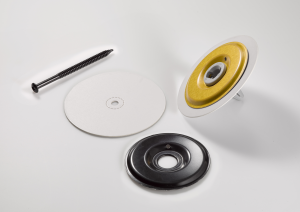

To enable use of the induction welding process with a broader range of rigid foam insulations, fastener manufacturers have developed a simple solution. For each fastener, crews place a thin disc between the fastener plate and insulation. This separation medium protects the EPS from the high heat of the induction welding process, without interfering with the bond between the membrane and the fastener plate. Manufacturers typically refer to these separators as “induction welding cardboard discs.” While they are paper-based products, calling them “cardboard” understates their performance, as they are densely compressed and have a moisture-resistant coating, so they work well in high-performance roof systems.

Why This Matters

For roofers who prefer using EPS insulations for the products’ thermal performance and ease of installation, the discs allow them also to achieve the benefits of the induction welding process discussed above.

Induction welding cardboard discs enable use of the induction welding attachment process for TPO and PVC membranes over EPS insulation. Photo: Insulfoam

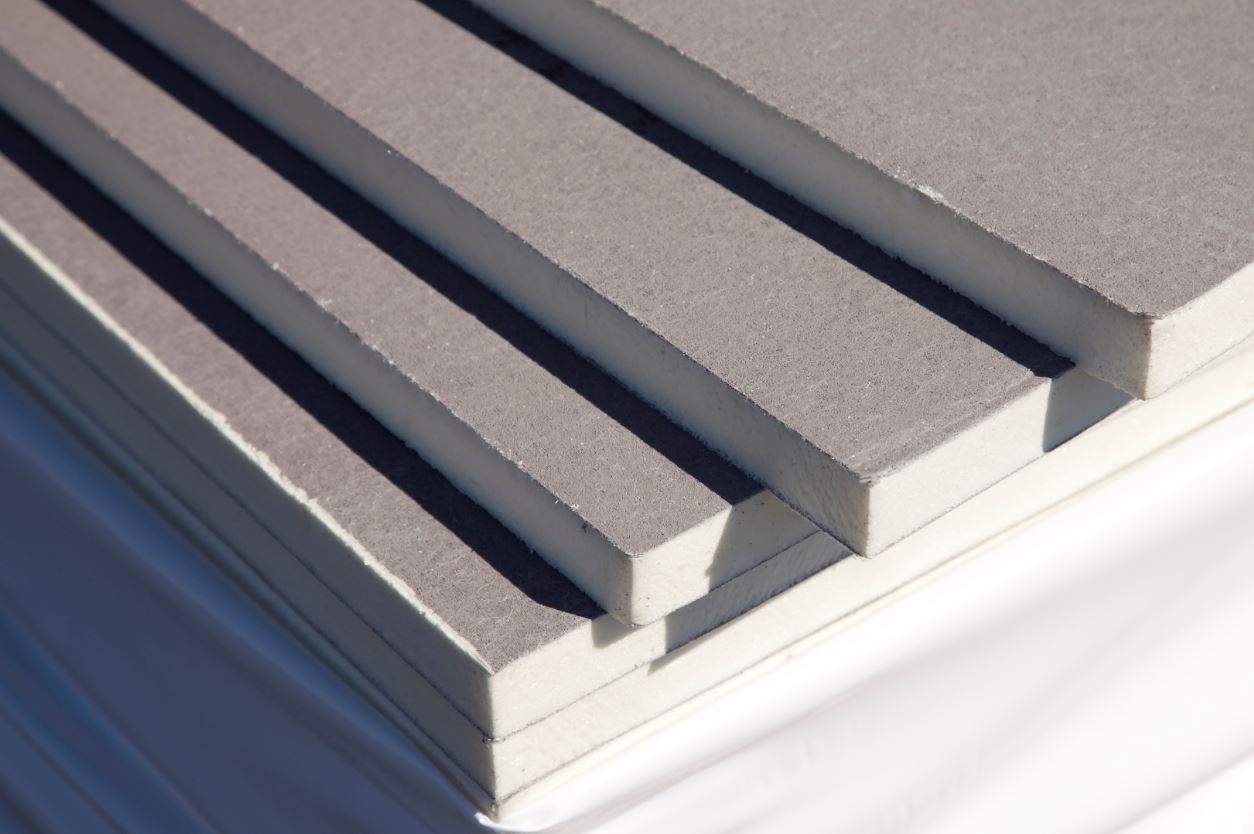

While induction welding has always been possible using EPS insulation products that have standard cover boards, the discs make it possible to induction weld over EPS products with glass facers and fanfold EPS with polymeric facers. Glass-faced EPS products can be used in new applications and recovers while roofers typically use fanfold EPS in roof recovers.

Fanfold EPS bundles, like R-TECH FF and others, are available in standard sizes up to 200 square feet, comprised of 25 panels that are 2 feet by 4 feet each, and come in various thicknesses. A typical two-square bundle weighs less than 11 pounds, so it is easy for one person to carry. EPS fanfold bundles require fewer fasteners per square foot than most roofing insulations and are less expensive than virtually every recover board. The man-hours needed to install fanfold bundles are about 60 percent less than working with individual sheets. Material costs are also lower than wood fiber, perlite, or gypsum board. On large projects, the

Induction welding typically requires fewer fasteners and plates than mechanically fastened applications, resulting in both labor and material savings. Photo: OMG

total savings can add up to tens of thousands of dollars. As with other EPS insulations, the product’s light weight also means less crew fatigue.

As roofers look for ways to create cost-effective, high-quality roof assemblies, new methods provide the opportunity to boost the bottom line by reducing labor and material costs. A simple, affordable disc now enables you to obtain the benefits of both the induction welding method for fastening TPO and PVC membranes and the advantages of EPS insulations.

Be the first to comment on "Easy-to-Use Discs Enable Induction Welding of PVC and TPO Membranes Over EPS Insulations"