Recently while preparing training for our team on how to ensure that the edge metals that we install comply with building code, inconsistencies and confusion about regulatory compliance caused me to dig deeper. Specifically, my questions related to ANSI/SPRI/FM 4435/ES-1 2017. The requirements of section 3.0 (shown below) caused the greatest concerns:

3.0 Membrane Termination

Two types of membrane termination are industry accepted: dependently and independently terminated systems.

3.1 Dependently Terminated Systems

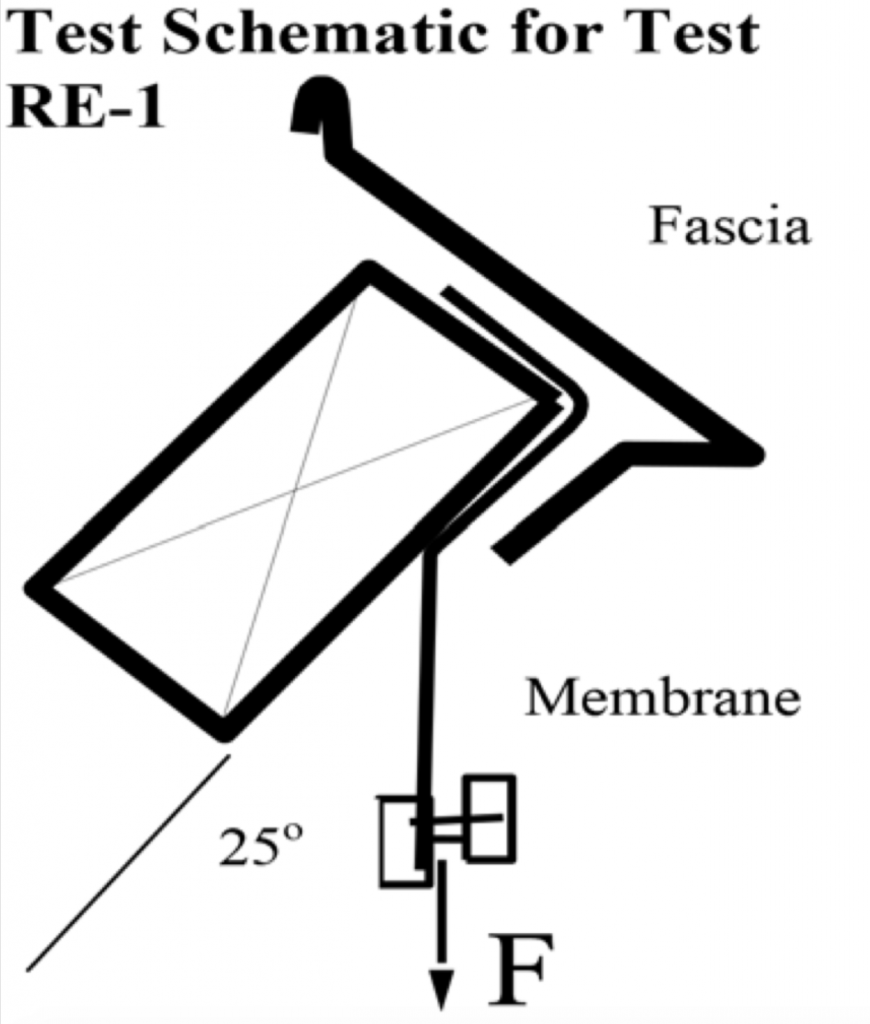

Ballasted systems, ribbon/spot adhered systems, or systems in which the mechanically attached roof over is secured to the substrate at a distance greater than 12 in (300 mm) from the roof edge are considered dependently terminated by the roof edge system. For these systems the RE-1 and RE-2 tests are required.

3.2 Independently Terminated Systems

Systems in which the roof cover is fully adhered to the substrate or a mechanically attached roof cover is secured to the substrate at a distance less than or equal to 12 in (300 mm) from the roof edge are considered independently terminated. For these systems the RE-2 test or RE-3 test is required.

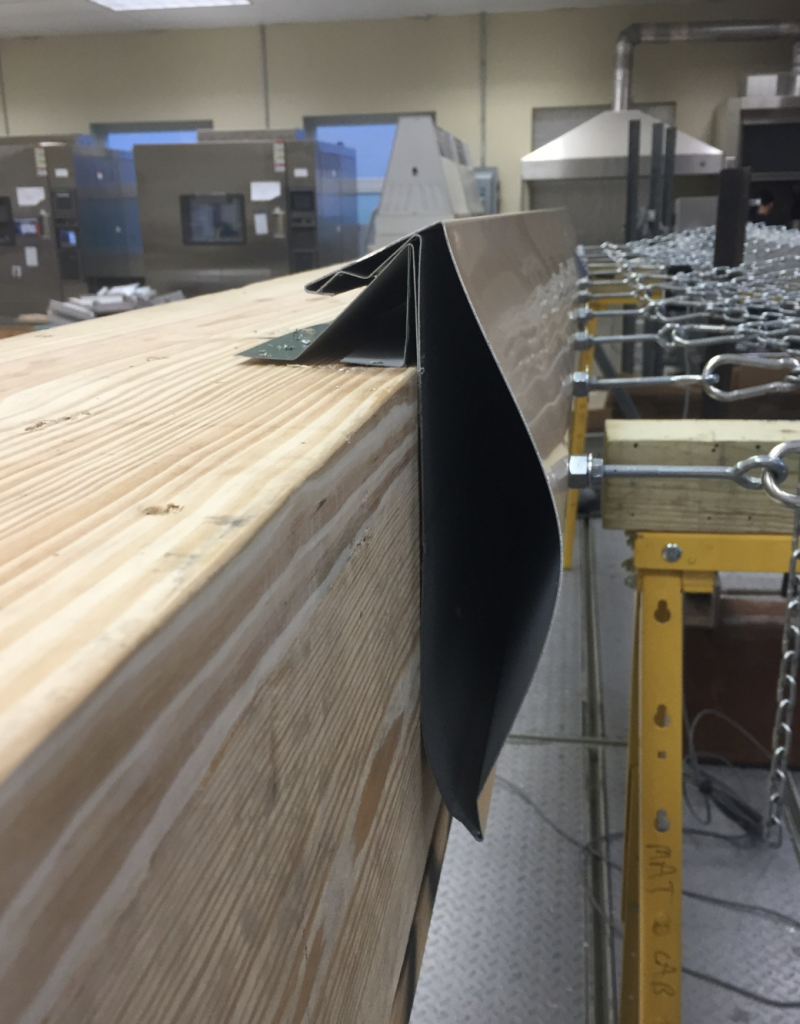

Many installed roof systems are mechanically fastened thermoplastic with fastener row spacing that exceeds the 12-inch requirement, and often snap-on fascia systems are utilized to meet the owner/designer’s price concerns. The product data sheets for most of prefabricated snap-fascia cover systems frequently contain the following statement(s):

• ANSI/SPRI/FM-4435 ES-1 Tested and Certified.

• Quality Assurance: The fascia product shall be listed in the current Factory Mutual Research Corporation Approval Guide approved by ANSI/SPRI/FM 4435/ES-1 SPRI Test Method RE-2 Pull-Off test for fascia. Fascia shall be certified by the manufacturer to design pressures as indicated in current edition of Wind Resistance Standard for Edge Systems Used with Low Slope Roofing Systems.

It was the last few sentences which concerned me as a roofer. If the systems are only tested for RE-2, then it is likely that ballasted systems, ribbon/spot adhered systems, or systems in which the mechanically attached roof cover is secured to the substrate at a distance greater than 12 inches (300 mm) from the roof edge that incorporate this edge flashing may not comply with building codes.

In hopes of finding an edge metal detail that was tested for RE-1 per ANSI/SPRI/FM 4435/ES-1, the NRCA Technical Services was contacted. This resulted in the revelation that RE-1 testing cannot be performed for generic membrane types. Rather, the testing would have to be performed on each type of membrane for each manufacturer. This is due to many factors related to the typical properties of each membrane type and manufacturer. These factors can include type of reinforcement (if any), mixture components, type of manufacturing process, etc. Therefore, the testing data can be proprietary.

Now, as a roofing contractor, I am really confused.

1. The building code tells me that the edge metals we install must:

1504.5 Edge securement for low-slope roofs.

Low-slope built-up, modified bitumen and single-ply-roof system metal edge securement, except gutters, shall be designed and installed for wind loads in accordance with Chapter 16 and tested for resistance in accordance with Test Methods RE-1, RE-2 and RE-3 of ANSI/SPRI ES-1, except Vult wind speed shall be determined from Figure 1609A, 1609B, or 1609C as applicable.

2. ANSI/SPRI/FM 4435/ES-1 states:

Membrane Termination

Two types of membrane termination are industry accepted: dependently and independently terminated systems.

3.1 Dependently Terminated Systems

Ballasted systems, ribbon/spot adhered systems, or systems in which the mechanically attached roof cover is secured to the substrate at a distance greater than 12 in (300 mm) from the roof edge are considered dependently terminated by the roof edge system. For these systems the RE-1 and RE-2 tests are required.

3.2 Independently Terminated Systems

Systems in which the roof cover is fully adhered to the substrate or a mechanically attached roof cover is secured to the substrate at a distance less than or equal to 12 in (300 mm) from the roof edge are considered independently terminated. For these systems the RE-2 test or RE-3 test is required.

3. We now know that RE-1 testing cannot be uniformly tested for each type of roof membrane. Therefore, it is not always readily available.

4. Of the pre-manufactured edge metal suppliers that were contacted, some indicated they tested per RE-1, while others agreed that they only tested to the RE-2 standard, and some went so far as to say that RE-1 test does not relate to their product. However, ANSI/SPRI/FM 4435/ES-1 2017 states otherwise.

Ongoing Questions

Should all roofing contractors go ahead and install the securement within 12 inches of the roof edge to ensure that all non-adhered roof systems are independently terminated, avoiding the need for RE-1 testing? Worse yet, should we install fasteners in ballasted roof systems since passing RE-1 test data is not readily available? Fasteners in the field of a ballasted roof can be a disaster. (One option that contractors can use to avoid the need for RE-1 testing is by installing a peel stop.) The question remains: Is confusion about RE-1 and ANSI/SPRI/FM 4435/ES-1 driving contractors to install independently terminated roof membrane systems?

When all is said and done, it is the roof installer that is ultimately responsible for proper application of the product to meet the legal requirements. It appears that there is ambiguity and confusion concerning ANSI/SPRI/FM 4435/ES-1 and code compliance. We can only hope that this will be clarified by building professionals, rather than lawyers. In the interim, we are now aware of the potential issues and can react as we deem necessary to mitigate our liability.

About the author: Andy Baker is vice president of Baker Roofing, headquartered in Raleigh, North Carolina. He has 40 years of experience in the construction industry, 33 of which have been exclusively related to roofing, from roofer to vice president. For more information, visit www.bakerroofing.com.

Be the first to comment on "Is There Ambiguity About Regulatory Compliance With Edge Metal Systems?"