What are the differences among paints and roof coatings, and what are liquid-applied membranes? The purpose of this article is to define these products and systems to establish guidance for their selection and use and to identify what factors favor specifying a liquid-applied solution versus a prepared roofing solution.

Paint: A finish where cosmetics are typically a primary attribute. Surface protection may also be a key selling point, but as a rule paint must look good. Paint is sold in specific sheen levels and in a broad range of colors. It usually has limited flexibility, but its hardness provides for exceptional weathering and colorfastness in a thin film.

Coating: A protective film used to provide surface protection or other resistance property. Color range and appearance are determined completely by performance considerations. A coating generally has an elongation greater than 100 percent, good low-temperature flexibility, is high in solids, and requires a thicker film to achieve long-term weathering and waterproofing.

Liquid-applied Membrane: A fully reinforced system composed of a fabric and one or more coatings or resins, used to encapsulate and adhere the reinforcement.

Paints, coatings, and liquid-applied membranes are all polymer-rich and share a few key attributes. They are usually based on resins that possess very good weathering resistance and are frequently cross-linked in some fashion to confer toughness and chemical resistance. They are somewhat over-engineered to compensate for the vagaries incumbent with field application.

Paints

Paint applications in roofing are almost exclusively used on steep-slope metal systems for aesthetic or reflective purposes. When metal comes painted from the factory, it is called an Original Equipment Manufacturer (OEM) paint; these baked metal finishes are usually more durable than an aftermarket maintenance coating. Although not intended to improve the water shedding of the roof system, a metal roof may still benefit from the corrosion-inhibiting, temperature-reducing and eye-appealing properties of a paint job.

Steep-slope metal roofs are often important architectural details. Bare metal, despite its luster, has only moderate solar reflectivity and fairly poor emissivity, so it gets very hot. All paints, even dark ones, allow more heat to escape the metal, lowering the peak temperature of the roof. Paints with deep colors can employ special pigments that absorb less heat from the sun.

Most white roof paints are rated for their solar reflectivity and emissivity. Together, these values produce a Solar Reflective Index that can predict the peak surface temperature. In terms of cool roofing, no better improvement exists for metal than coating a rusting metal roof with a white coating. Often these roofs are not well insulated and, as they rust, they become less reflective, holding and conducting heat into the building, which dramatically increases the load on air conditioning. Ultimately, paint can be seen as the first step in a long-term maintenance program that might later involve coatings or membranes.

Coatings

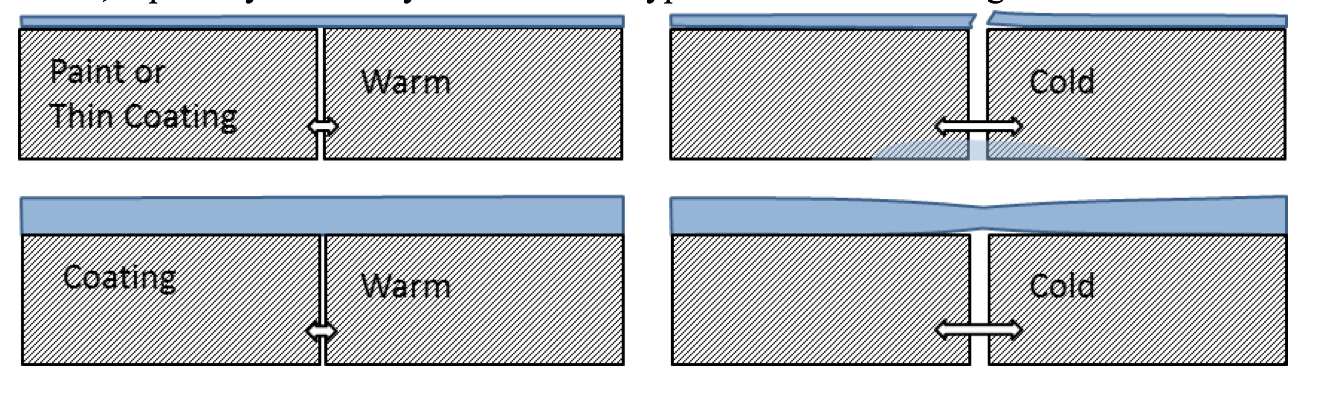

Today, most coatings are based on acrylic, silicone or urethane resins. All seek to extend the service life of the existing roof and, as a rule, prevent the intrusion of water. To do this requires a much higher degree of crack bridging than found in paint. A coating must be able to protect a number of transitions that are subject to cyclical movement: flashing to the membrane, flashing to the structure, joints at protrusions and curbs, and any seams within the membrane. This implies an appropriate degree of low-temperature flexibility, substantial elongation and a thick film. A coating should never be used to overcome a structural issue and, while they must tolerate movement, coatings cannot overcome the limitations of an improperly engineered roof system.

Although many of today’s coatings are sold as part of a cool roof solution, in sunnier climates it is important to recognize that a coating shouldn’t be selected like a paint—strictly on appearance or reflectivity. A coating should provide robust barrier properties, starting with increased water resistance, and often include some combination of chemical resistance (plasticizers, oils, stack emissions) and resistance to abrasion, impact or vapor intrusion (water, oxygen, CO2).

Typically, coatings properties include tensile and elongation, values that are usually reported at standard temperature and humidity. Crack bridging is the key to performance; it’s a function of elongation at a low temperature, tear strength and film thickness. When a material is tested to an ASTM material standard, that protocol will include tear strength, a low-temperature flexibility test and some weathering values. Let’s examine the typical properties and explore what they mean and do not mean.

Be the first to comment on "Paints, Coatings and Liquid Membranes"