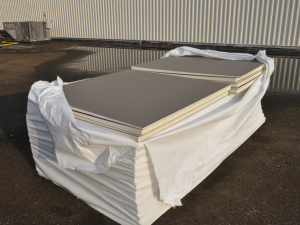

That being said, each polyisocyanurate insulation manufacturer offers its own version of a “premium” higher-density and non-organic facer polyisocyanurate insulation. The premium insulation offers the same thermal attributes as the standard polyisocyanurate offering but provides a better substrate in three important areas: better foam density, better dimensional

stability and the non-organic facer will not readily absorb water. Each of these attributes makes the premium non-organic facer insulation an excellent substrate for a roof system.

I recommend the use of the premium insulation to all building owners and with all roof systems. Upgrading from the standard polyisocyanurate insulation to the premium polyisocyanurate insulation provides an excellent cost to benefit ratio.

Above-deck insulation in a low-slope roof system provides the insulation that completes the thermal envelope of a building. Other building components—doors, walls, windows, etc.—are the remaining pieces of the thermal envelope.

The current industry standard for polyisocyanurate insulation comes with an organic facer and a published density of 20 psi.

The thermal envelope as a whole (not just the roof insulation) and the efficiency of the heating and cooling equipment in place affects the energy efficiency of a building. The industry has created the perception that the amount of insulation in a building’s roof system is the primary component determining how much it costs to heat and cool a building.

The optimal insulation solution from an R-value perspective is primarily influenced by the building use. For example, a freezer building will have a different insulation solution than an unheated warehouse. We will stick with the Pareto, or 80/20, rule here: Approximately 80 percent of buildings will fall into the “typical” category, meaning that the optimal amount of insulation will be in the 3.5- to 5-inch total thickness range. All insulation assemblies should always be installed in two layers to allow for staggering the joints of the insulation.

INSULATION’S LONG-TERM VALUE

A building owner making a roofing decision should be encouraged to take the time to understand the long-term financial ramifications of the roof design and insulation assembly for the new roof system. In most cases, the insulation is the most expensive component of a new roof assembly. Often, a building owner does not understand how the insulation selection made today is really a long-term financial decision.

When considering the purchase of a new roof, a building owner is often making a large capital purchase decision of a product he does not truly understand. The inexperienced roofing decision-maker often resorts to making the roofing purchase decision based on cost and warranty. Because insulation is the most expensive component of a roof assembly, most often the quantity of insulation is the first item to be minimized.

It is the responsibility of the roofing professional providing advice to the building owner to help the building owner understand the long-term effects of the insulation decision being made for the new roof system. The insulation decision today is really a decision that will affect the overall cost of roof and building ownership over the long term.

PHOTOS: BLOOM ROOFING

Great points, not enough people take this in to consideration!