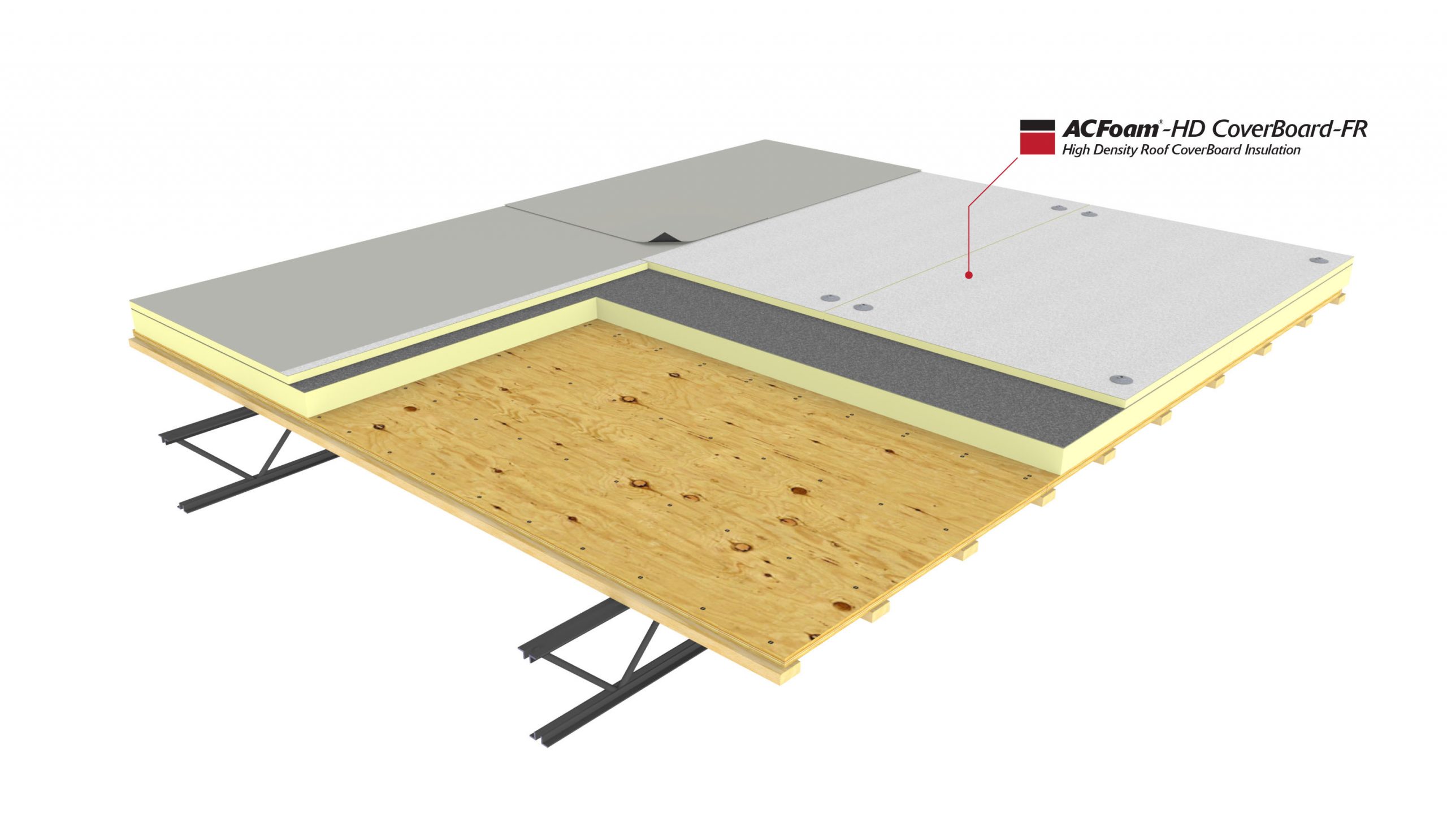

Atlas Roofing Corporation Unveils New Brand as Company Celebrates 40th Anniversary

Atlas Roofing Corporation unveiled a new brand identity to further reflect its passion and commitment to creating solutions with a purpose. The rebrand, which encompasses a…