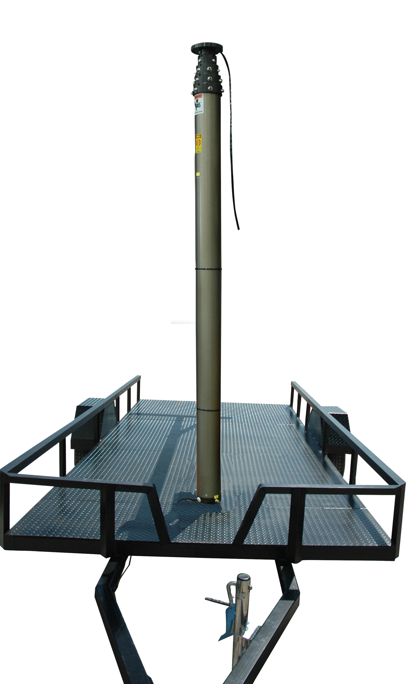

LED Mini Light Tower Illuminates an Area Greater than 45 Feet Long and 35 Feet Wide

Larson Electronics releases a 12-watt temporary fixed-mount LED mini light tower for general close work areas and for other applications where an easily deployable and…