Forward-Thinking SIPs Hold the Keys to Energy-Efficient Structures

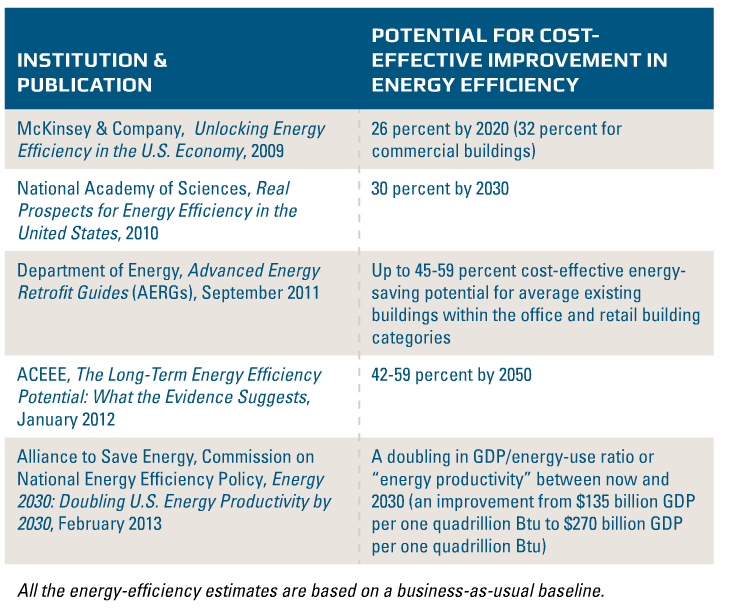

High-performance, energy-efficient buildings are a critical component of the global transition plan to a lower-carbon future. This puts enormous responsibility on the shoulders of building…