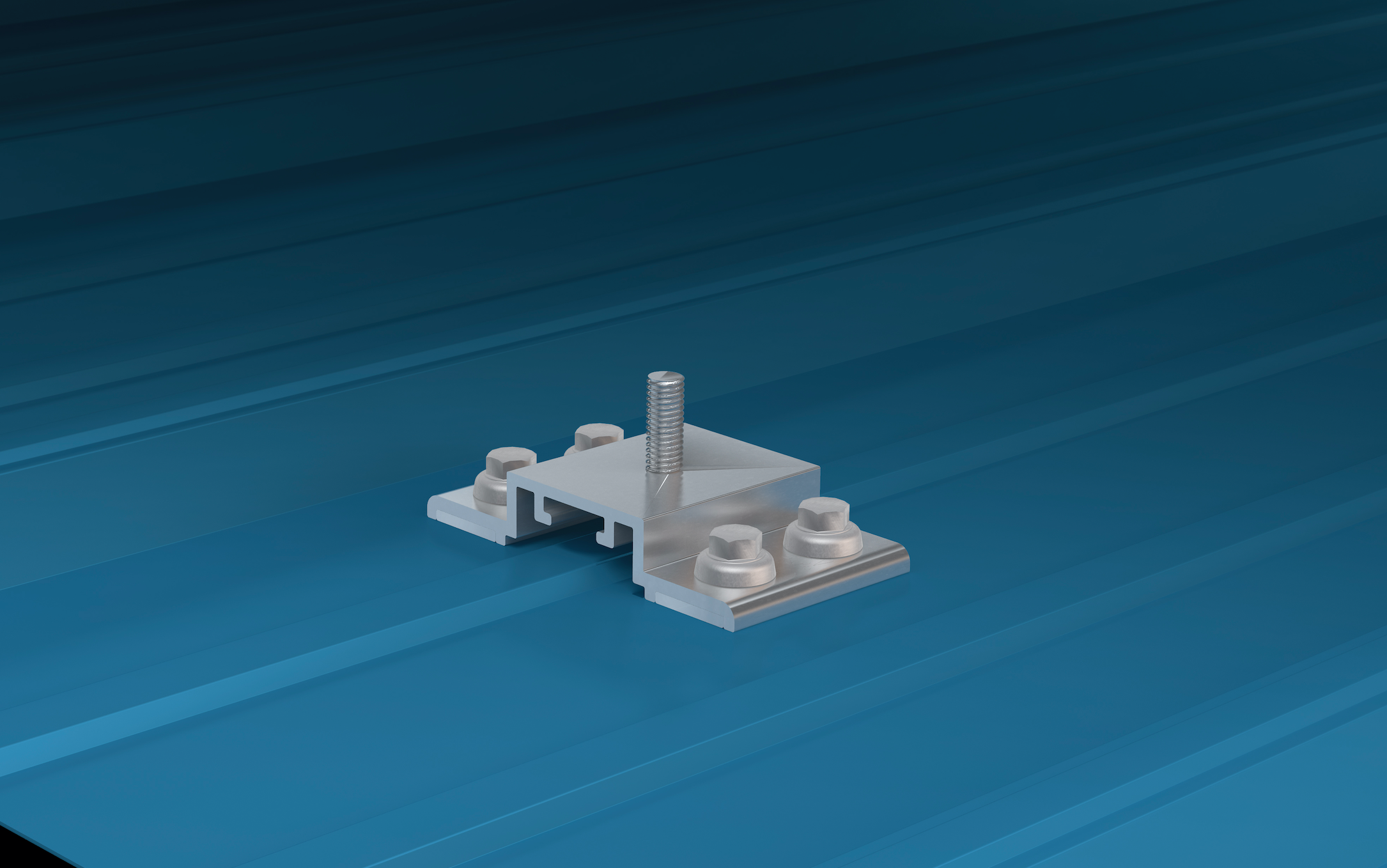

New Electrical Conduit Clamp For Metal Roofs

S-5! introduces its new electrical conduit clamp for metal roofs. The new CanDuit clamp secures and supports electrical conduit, cable trays, gas piping, condensate lines, chases, and other round-shaped objects…