The primary and most important function of a roof membrane in a low-slope roof system is to provide weatherproofing by keeping the rainwater from entering the roof assembly. Ponding water poses the greatest risk to a roofing membrane, since it not only shortens its service life, but can lead to more serious life safety concerns when loads and deflections exceed the designed conditions. This could lead to a roof collapse. From an aesthetics standpoint, areas on roofs with a prevalence for ponding are susceptible to unsightly bacterial and algae growth as well as accumulation of dirt. Given the large footprint of low-slope roofs on typical commercial buildings, managing rainwater timely and effectively is an important design consideration in new roof design as well as roof replacements on existing buildings. In addition, the model building codes include requirements for minimum drainage slope and identify ponding instability as a design consideration for rain loads.

Tapered insulation systems are an integral part of roof system design and can help reduce or eliminate the amount of ponding water on the roof when the roof deck does not provide adequate slope to drain. The popularity of tapered insulation has grown as more designers and roofing professionals understand the importance of positive drainage in good roofing practice. Because of its wide use in low-slope roofing application, tapered polyiso insulation systems offer a number of benefits in addition to providing positive drainage: high R-value, versatility and customization to accommodate project-by-project complexity as well as ease of installation. This article highlights the key considerations for tapered insulation systems.

Slope and Drainage Requirements in Building Codes

The model building codes require that commercial roofs be sloped to achieve a positive drainage of rainwater to drains, scuppers, and gutters. The term “positive roof drainage” is defined in the 2018 International Building Code (IBC) as “the drainage condition in which consideration has been made for all loading deflection of the roof deck, and additional slope has been provided to ensure drainage of the roof within 48 hours of precipitation.” The 2018 IBC indicates a minimum design 1/4:12 units slope requirement for membrane roof systems, and minimum slope of 1/8 inch per foot for coal tar pitch roofs. New construction must comply with the minimum slope requirements in IBC Section 1507. Roof replacement or roof re-cover applications of existing low-slope roof coverings that provide positive roof drainage are exempt from the minimum prescriptive1/4:12 units slope requirement.

Roof drains are part of an approved storm drainage system and function to divert water off and away from the building. Roof drainage systems in new construction must comply with provisions in Section 1502 of the 2018 IBC and Section 1106 and 1108 of the International Plumbing Code (IPC) for primary and secondary (emergency overflow) drains or scuppers. Roof replacement and re-cover applications on existing low-slope roofs that provide positive roof drainage are exempt from requirements for secondary drains or scuppers. It is important to note that secondary drainage systems or scuppers in place on existing buildings cannot be removed unless they are replaced by secondary drains or scuppers designed and installed in accordance with the IBC.

When reviewing the options available for achieving the required slope in a roof system, designers have a number of choices. According to the National Roofing Contractors Association (NRCA) (see “The NRCA Roofing Manual: Membrane Roof Systems: 2019”) the slope can be achieved by: sloping the structural framing or deck; designing a tapered insulation system; using an insulating fill that can be sloped to drain; properly designing the location of roof drains, scuppers and gutters; or a combination of the above.

Design Considerations For Tapered Insulation Systems

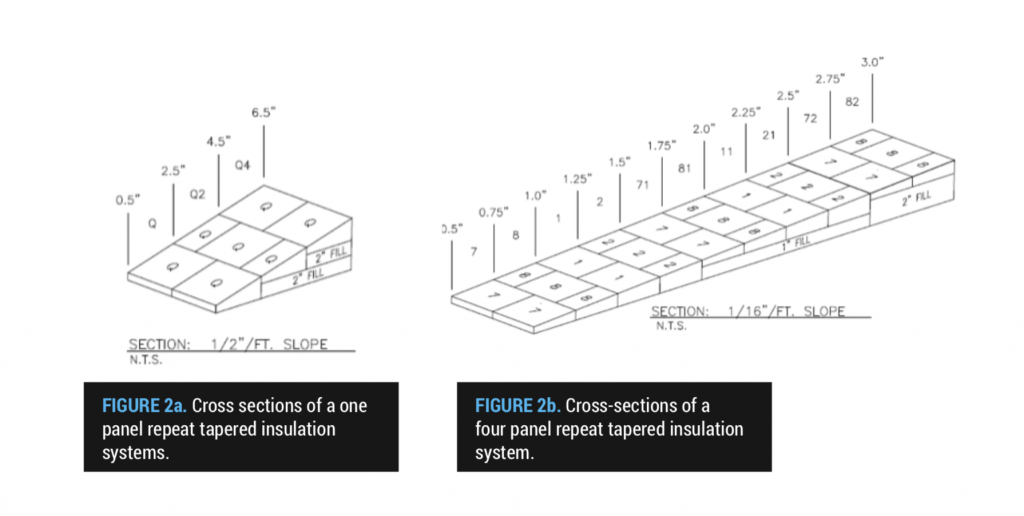

Proper design and installation are critical to the effective performance of tapered polyiso insulation systems, and this is true for any product or system. Tapered polyiso is manufactured in 4-foot-by-4-foot or 4-foot-by-8-foot panels that change thicknesses over the 4-foot distance from the low edge to the high edge on the opposing sides of the panel. The standard slopes for tapered insulation are 1/8 inch, 1/4 inch and 1/2 inch per foot to accommodate specific project requirements. However, tapered insulation panels with slopes as low as 1/16 inch and other alternative slopes (3/16 inch and 3/8 inch per foot) can be specially ordered to accommodate unique field conditions. The minimum manufactured thickness of tapered polyiso insulation board at its low edge is 1/2 inch and the maximum thickness at the high edge is 4-1/2 inches.

The design of the tapered insulation system will be governed by the footprint and complexity of the roof under consideration, slope of the roof deck, presence and configuration of roof drains (primary and secondary), scuppers, gutter or drip edges. In addition, roof structures, height of parapet walls, expansion joints, curbs and through-wall flashings and any other elements that may obstruct water management also needs to be considered in the design phase. The tapered insulation system will be lowest at internal drains, scuppers, gutters and drip edges, and will slope upwards away from these features.

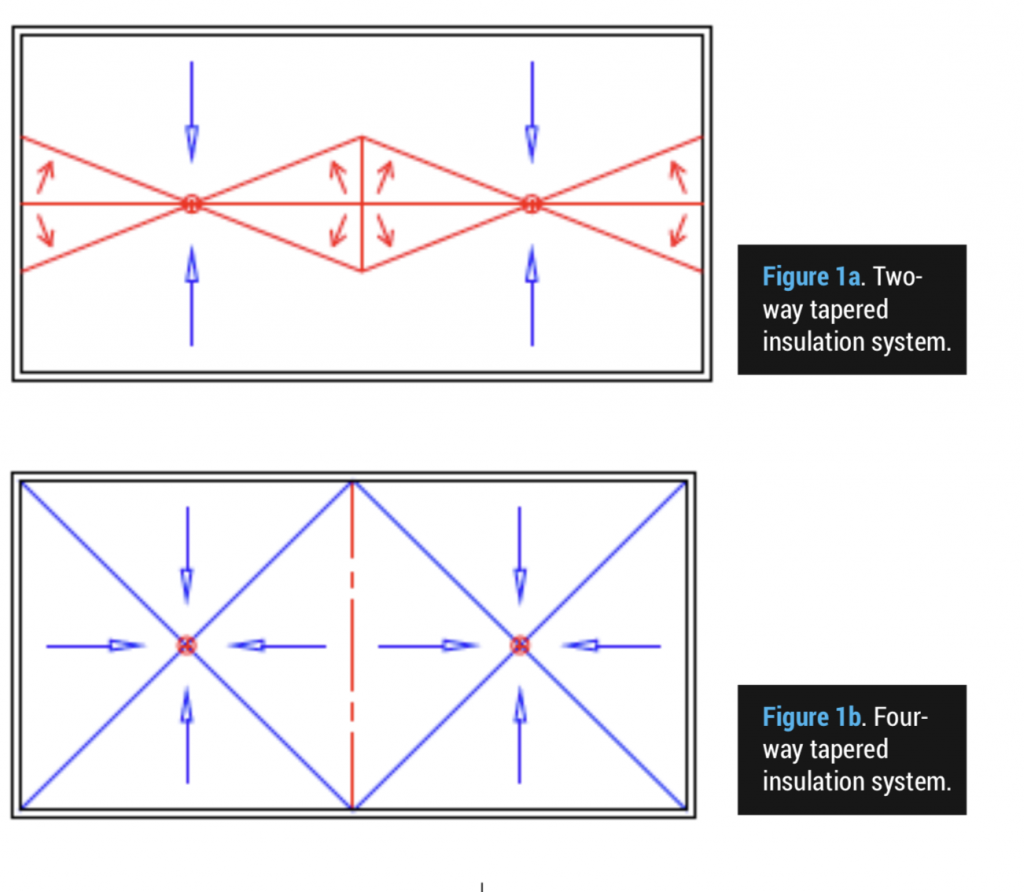

Keeping in mind that the primary goal of a tapered insulation system is to most effectively move water to the specified drainage points. A two-way (two directional slope) or four-way (four directional slope) system are the most common designs. A two-way tapered insulation system is commonly used on roofs where multiple drains are in straight lines. In this scenario, there is a continuous low-point between the drains and it often extends to the parapet walls. Crickets are installed in between the drains and between the building or parapet walls and the drains. (See Figure 1a.)

A four-way tapered insulation system is the most effective way to move water off the roof, and this approach is highly recommended by industry professionals. In this scenario with a drain located in the center, water is drained from the higher perimeter edges on all four sides. (See Figure 1b.) Variations of two-way and four-way systems exist to accommodate complexities in the field. In addition to two-way and four-way systems, one directional slope and three directional slope tapered systems can be used to effectively move water to gutters, drip edges and scuppers.

Keeping in mind that a tapered system is more expensive than a roof system constructed with standard flat insulation only, the tapered design is often a target for “value engineering.” Value engineering can compromise the drainage intent of the design professional, architect or roof consultant for the purpose of lowering the installed cost of the roof system. Value engineering may change the specified slope or redesign the configuration of the tapered panels. In the end, the building owner may pay for a tapered insulation system that does not effectively drain water from the roof as intended by the original design. This will likely result in higher long-term costs for roof maintenance and premature roof system failure.

A typical tapered insulation system will incorporate flat polyiso board stock (referred to as “fill panels” or “tapered fill panels”) beneath continuing, repeating tapered panels. The tapered panels can be a single panel (or “one panel repeat”) system, meaning that the taper is provided by a single repeating panel in conjunction with fill panels. (See Figure 2a.) Non-typical designs can feature up to an eight-panel (or “eight panel repeat”) system with eight tapered panels making up the sloped section prior to incorporating the first fill panels. An example of “four panel repeat” system with 1-inch and 2-inch fill panels and 1/16 inch per foot slope is provided in Figure 2b.

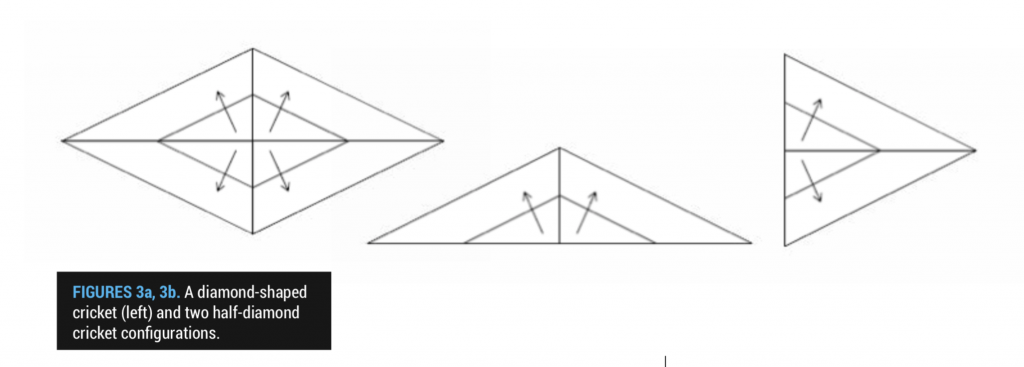

Finally, crickets are an integral part of a tapered insulation system and are commonly used in two-way systems. Crickets can divert water toward drains and away from curbs, perimeter walls, and roof valleys. The two factors that must be considered in the design and installation of crickets are slope and configuration. The general “rule of thumb” is that for a full diamond cricket the total width should be between 1/3 to 1/2 of the total width. The wider the design of the cricket, the more you utilize the slope in the field of the roof, which improves the drainage efficiency.

Crickets typically have diamond or half-diamond shapes. (See Figures 3a and 3b.) However, kite-shaped and snub nose crickets can also be configured to accommodate specific roof designs. To keep water from remaining on the cricket surface, the design needs to have a sufficient slope (generally, twice the slope in the adjacent field of the roof). NRCA provides guidance regarding cricket geometry (see “The NRCA Roofing Manual: Membrane Roof Systems: 2019”).

Tapered insulation systems offer a cost-effective solution to achieving positive slope and improved drainage in new roof systems and roof replacement applications. An adequate rainwater management strategy that includes both proper drainage and elimination of ponding water is critical to the long-term performance and durability of a roof system. In addition, proper design, detailing, and installation of products must be an integral part of a tapered roof system design. For more information, consult with a polyiso insulation manufacturer who provide guidance, design assistance, and technical information regarding tapered insulation systems. In addition, the Polyisocyanurate Insulation Manufacturers Association (PIMA) publishes technical bulletins to help navigate the process of designing a tapered system. PIMA’s Technical Bulletin #108 on Tapered Insulation Systems can be found at www.polyiso.org/resource/resmgr/Tech_Bulletins/tb108_Mar2017.pdf.

About the author: Marcin Pazera, Ph.D., is the Technical Director for Polyisocyanurate Insulation Manufacturers Association (PIMA). He coordinates all technical-related activities at PIMA and serves as the primary technical liaison to organizations involved in the development of building standards. For more information, visit www.polyiso.org.

Be the first to comment on "Tapered Insulation Can Prevent Ponding on Low-Slope Roofs"