ADDITIONAL CONSIDERATIONS

From my experience, here are a few additional considerations for when I might use a vapor retarder in regions where the moisture drive is from the interior outward (typically ASHRAE zones 3 through 8). This is a condition that needs to be determined by the designer and is based not only by region, but also by micro-climates and building use.

▪▪ If the building is to be positively pressurized and the anticipated roof system is to be mechanically attached, a vapor retarder should be considered. These roof systems can work to “pump” interior air up into the roof system. Even those utilizing the RhinoBond attachment system should consider a vapor retarder. Yes, I know a mechanically fastened system would penetrate the vapor retarder, but the air infiltration will be greatly reduced. Also noteworthy: Two layers of insulation with staggered joints does not prevent air infiltration into the roof system, it just slightly delays the inevitable.

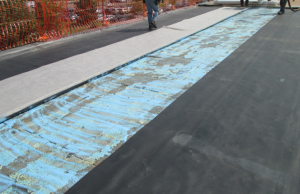

PHOTO 3: Fleece-back EPDM set in full-coverage spray foam on a concrete roof deck provides a superior vapor retarder without the use of torches or asphalt. It also can be integrated in the roof system’s and manufacturer’s warranties.

▪▪ If the building contains large open interior spaces where thick concrete pours are intended, consider a vapor retarder. Four inches of concrete can release 1 ton of water per 1,000 square feet of concrete. A vapor retarder will keep this moisture out of the roof system.

▪▪ If a warehouse and large amount of wood crating is anticipated, consider a vapor retarder. Wood can absorb a great deal of moisture in transport. The moisture will be released once stored in the interior, which will increase interior air moisture content that will move toward the roof system in warm air. A vapor retarder will keep this moisture out of the roof system.

▪▪ If large overhead doors are present, consider a vapor retarder. These buildings can be internally pressurized due to high winds and work to push the roof off the deck. A vapor retarder keeps the wind pressure on the roof deck and not in the roof system.

▪▪ If wind-uplift analysis is severe, a vapor retarder will assist in wind-uplift resistance.

▪▪ If the building is considered an essential facility, such as a hospital, federal building, data center or bank, to name a few, consider a vapor retarder.

The type of roof deck selected by the engineer and/or existing roof deck is a consideration, as well. Permeable decks, such as steel, that do little to restrict airflow, and poured concrete decks, which are never given enough time to dry out, should be considered regardless of the interior building use. The type of roof system should also be considered in concert with the type of roof deck.

PHOTO 4: Used with the manufacturer’s recommended adhesive, self-adhering membranes can provide sufficient vapor-retarder qualities.

TYPES OF VAPOR RETARDER SYSTEMS

Vapor retarders and vapor retarder systems (vapor retarders composed of more than one layer) come in a variety of materials and application methods, so that they can be successfully integrated into the roof system. Selecting a vapor retarder needs to be simultaneous with the building and roof system design because the final selection needs to take into consideration the roof-deck type and roof-system materials and attachment.

The following are roof-deck types and vapor retarders we have designed into various roof systems:

CONCRETE: CAST AND PRECAST

▪▪ Asphaltic two-ply with glaze coat (see photo 2)

▪▪ Modified bitumen: asphalt and torch-applied

▪▪ EPDM: adhered and loose laid

▪▪ Fleece-back EPDM (see photo 3)

▪▪ Self-adhering membrane with adhesive (see photo 4)

STEEL

▪▪ Polyethylene sheet (see photo 5)

▪▪ Self-adhering direct to deck

▪▪ Substrate board with

• Asphaltic two ply

• Modified bitumen

• Adhesive and self-adhering membrane

PHOTOS: Hutchinson Design Group Ltd.

Be the first to comment on "Vapor Retarders"