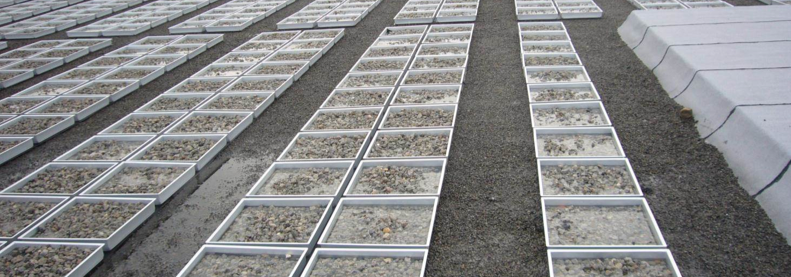

The rooftop on the Belfer Medical Research Building not only houses HVAC equipment but serves as a rainwater detention system. The reinforced membrane waterproofing system by Kemper System was applied to the roof deck before the pavers were put in place on a pedestal system.

Built for a cost of more than $630 million, the tower includes 13 stories of research laboratories. The tower has three roof levels at the 17th, 18th and 19th floors. The rainwater detention system, known as a “blue roof,” not only helps regulate storm water discharge, but it feeds a water fountain and irrigates planters on the second-floor terrace.

In general, rainwater detention systems can either collect water in holding tanks and then meter it to the public sewer system, or retain it on a waterproofed roof expanse. The blue roof on the Belfer Research Building uses the latter strategy. It complies with New York City requirements and can hold up to 3 inches of water.

Roof Materials

Proper waterproofing on the project is essential. The solvent-free and odor-free KEMPEROL 2K-PUR cold, liquid-applied membrane system was used for waterproofing the blue roof. It was also used on the terrace and fountains on the lower level. The reinforced membrane system is designed for long service life and backed by an extended-wear warranty.

Eagle One Roofing Contractors Inc. of Astoria, N.Y., a certified applicator of the Kemper System, applied the waterproofing system. The two-part resin system is designed to fully adhere to the substrate, and is fully reinforced with fleece. The resulting membrane is completely seamless and unaffected by ponding water and ice. According to the manufacturer, it resists exposure to UV light, chemicals, oils and solvents. It is impervious to bio-deterioration and is both root- and rot-resistant, so it is also ideal for green roofs and landscaped areas.

Roof Report

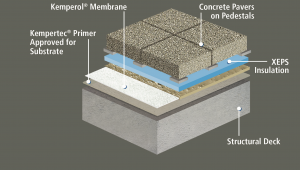

The supporting structure below the roof was designed to carry the water load, with an allowance for heavy snow or ice buildup. The roof deck is concrete slab and includes a layer of rigid insulation below the waterproofing membrane for added energy efficiency. The gravity-fed drainage system was carefully sized to control the speed of drainage without the use of pumps, sometimes required for rainwater detention systems that use holding tanks. On the roof sections, the waterproofing sections were topped with concrete pavers on a pedestal system.

Construction at the Weill Cornell Medical College, both interior renovations and new construction, is designed to meet a minimum LEED Silver status. This project was designed to achieve Gold certification, the nationally accepted benchmark for the design, construction and operation of high-performance green buildings.

This illustration shows the assembly used for the blue roof on this project. The cold, liquid-applied reinforced membrane system was topped by concrete pavers. Image: Kemper System America Inc.

The building includes a high-tech, multi-zoned HVAC control system to manage the indoor environment within different spaces. Biomedical laboratories, for example, generally require special air filtration systems supported by high-volume air circulation. Each of the laboratory levels includes four fume vents to the outside, except for the chemistry laboratory on the top floor, which uses 40 vents. In addition to thermostats and humidity sensors, indoor spaces utilize occupancy sensors to assist in regulating the ambient indoor environment and lighting to improve energy efficiency.

Photo: Kemper System America Inc.

TEAM

ARCHITECTS

Todd Schliemann, Ennead Architects, LLC, New York

William Cunningham, Weill Cornell Medical College, New York

ROOFING CONTRACTOR

Eagle One Roofing Contractors, Inc., Astoria, N.Y.

ROOF AND WATERPROOFING SYSTEM MANUFACTURER:

Kemper System America Inc., West Seneca, N.Y.

Be the first to comment on "Medical Research Facility Showcases Eco-Social Construction"