It was imperative to keep the facility dry and prevent debris from reaching the cosmetics’ production floor during roof construction to protect product purity. As an extra precaution, the owner had a flame-retardant cover suspended on the underside of the roof deck over the manufacturing portion of the building. Highland Commercial Roofing also kept the spray polyurethane foam rig onsite during the tear-off to use as a contingency plan in case of unpredicted rain; if rainwater seepage became a potential threat, the crew could quickly apply the foam to the roof deck to make the roof surface watertight.

SMOKE VENTS

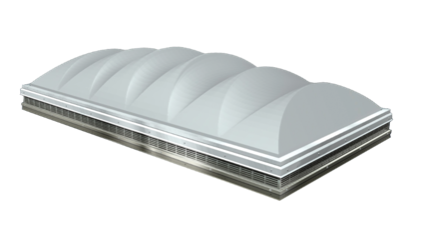

Another project challenge was that Highland Commercial Roofing was changing out 295 old skylights and smoke-vent skylights across the roof and replacing them all with new UL793-compliant vented smoke-vent skylights. “Because the owner frequently has employees on the roof to service the HVAC system, pumps and ventilation equipment specific to their manufacturing processes, we chose an incredibly durable smoke-vent skylight with a polycarbonate dome that has been impact and load tested to 800 pounds,” Cunningham says. “In addition, these units have a unique baffle system incorporated into their vortex vented base that, unlike traditional louvered-base vents, prevents water intrusion from wind-driven rain.”

Highland Commercial Roofing’s crew removed all the existing self-flashing skylights and smoke vents and built 2 by 10 curbs for all the new units. Prior to roofing, a 4-inch cant strip was in- stalled at the base of the curbs, followed by an SBS base sheet and cap sheet for extra waterproofing at this critical area. The new smoke-vent skylights sit on top of the curb offering easy removal for future replacement.

To protect against debris entering the facility through the vortex base vents, the crew secured a low-micron mesh particle filter inside each vent to provide maximum air exchange with minimal potential for debris entry into the building.

SUSTAINABLE SOLUTIONS

The new smoke-vent skylights have a translucent dome that provides abundant daylight to the interiors for energy savings. Employees are also treated to better quality light because the poly- carbonate skylight domes will not yellow as they age.

The new cold-applied roofing system is primed for long-term performance. If the owner upholds minimal annual maintenance responsibilities and agrees to pay for the UV reflective acrylic surfacing to be re-applied at the end of the initial 15-year system warranty period, the manufacturer will extend the roofing system warranty for an additional 10 years. “I’m certain the roof will last for at least another five or 10 years after that, making it a viable asset for more than 30 to 35 years,” Cunningham notes. “It’s a very sustainable choice.”

The system was designed to meet California’s Title 24 requirements and reduce thermal gain inside the building. The new roof installation included two plies of polyester reinforcement embedded in cold-applied asphalt emulsion, protected with white acrylic elastomeric surfacing. Photo courtesy of Highland Commercial Roofing.

Orchard says the roofing system was definitely the right decision for the building. “The installation was quiet, clean and fast,” he asserts. “The straight-line depreciation rate of the restoration system is equal to a single-ply membrane or a conventional built-up roof membrane, but this roof requires minimal maintenance and the projected serviceability and durability is much better. It was a very cost-effective solution and the owner is very happy with the result.”

ROOF MATERIALS

Roof System: Western Colloid

Spray Polyurethane Foam: Lapolla Industries Inc.

Smoke Vent Skylights: SKYCO Skylights

Flame-retardant Suspended Cover on Building Interior: TuffWrap

Be the first to comment on "Roof Sections of Cosmetics Manufacturing Facility Get Expert Makeover With Cold-applied System, SPF and Smoke-vent Skylights"