The Garlock Cyclone 5/15 Dual-Component Extruder is designed to significantly reduce the time and materials needed to adhere rigid insulation and cover boards to structural roof decks, as well as adhering fleece backed single-ply membranes in both new roofing and recover operations. According to the company, the Cyclone’s contained delivery system and free-flowing gun and hose design reduce the risk of catastrophic pump failure and costly downtime.

The Garlock Cyclone 5/15 Dual-Component Extruder is designed to significantly reduce the time and materials needed to adhere rigid insulation and cover boards to structural roof decks, as well as adhering fleece backed single-ply membranes in both new roofing and recover operations. According to the company, the Cyclone’s contained delivery system and free-flowing gun and hose design reduce the risk of catastrophic pump failure and costly downtime.

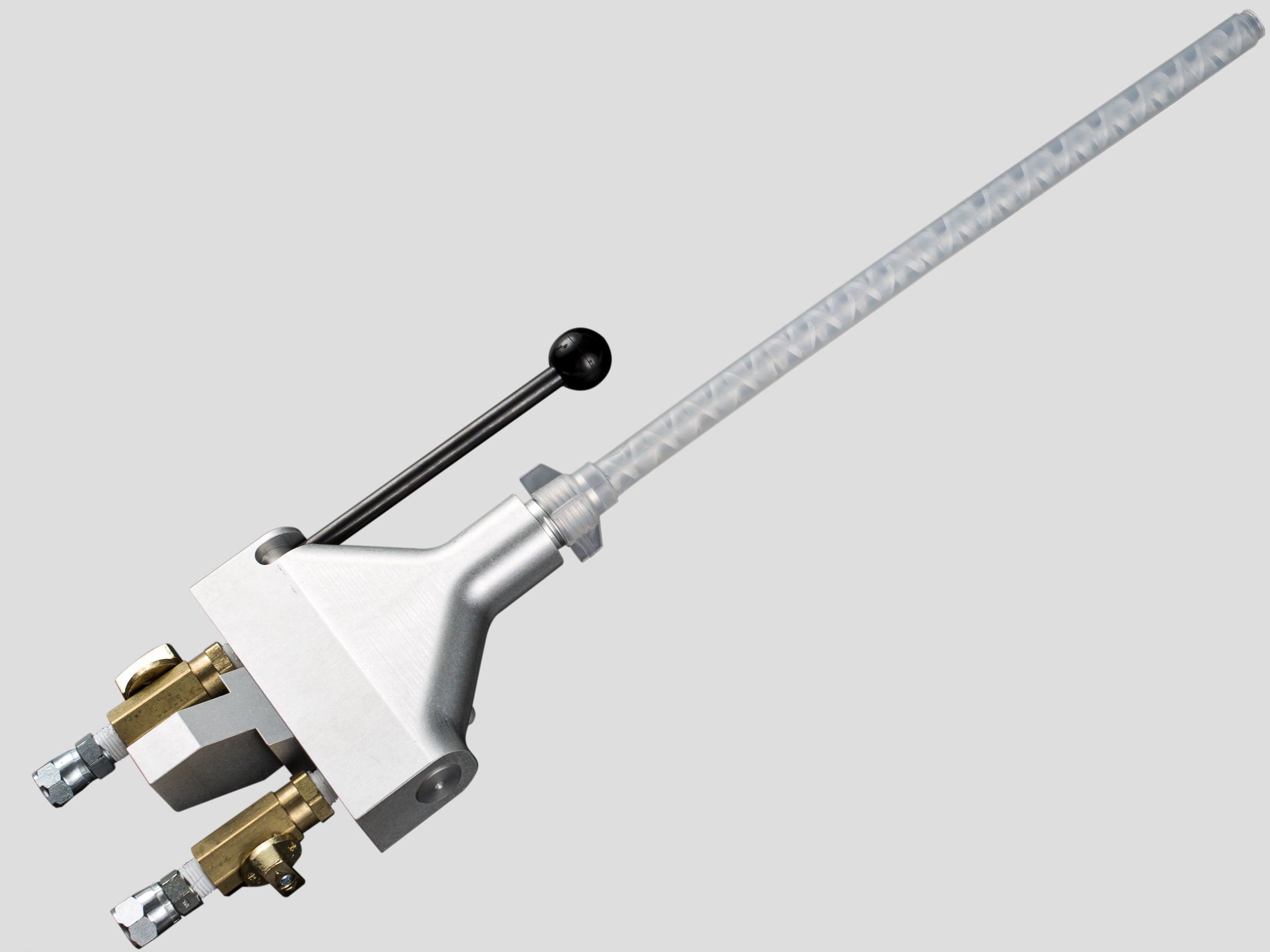

The Cyclone equally dispenses a two-component, 1:1 ratio low viscosity polyurethane adhesive, which allows projects to progress much more quickly than using multiple crews with hand caulking guns. Users can access connectors and load chemical containers from the front without kneeling or crouching, which minimizes downtime and operator fatigue. The Cyclone’s adjustable gun assembly and ergonomic design help reduce application errors and training time.

The product features a 1/2-HP electric motor, easy-loading barrel trays, and six solid rubber, flat-free tires. An optional generator mount allows an on-board generator to be tucked inside of the machine frame.

For more information, visit www.garlockequip.com.

Be the first to comment on "Dual-Component Extruder Designed to Minimize Downtime"