Contractors working across state lines are all too familiar with the challenges that arise when regulations in one state are not consistent with the regs in the state next door — or two states over. One of the hardest types of regulatory change to manage occurs when rules regarding material performance shift on a state-by-state basis and are applied at differing timelines.

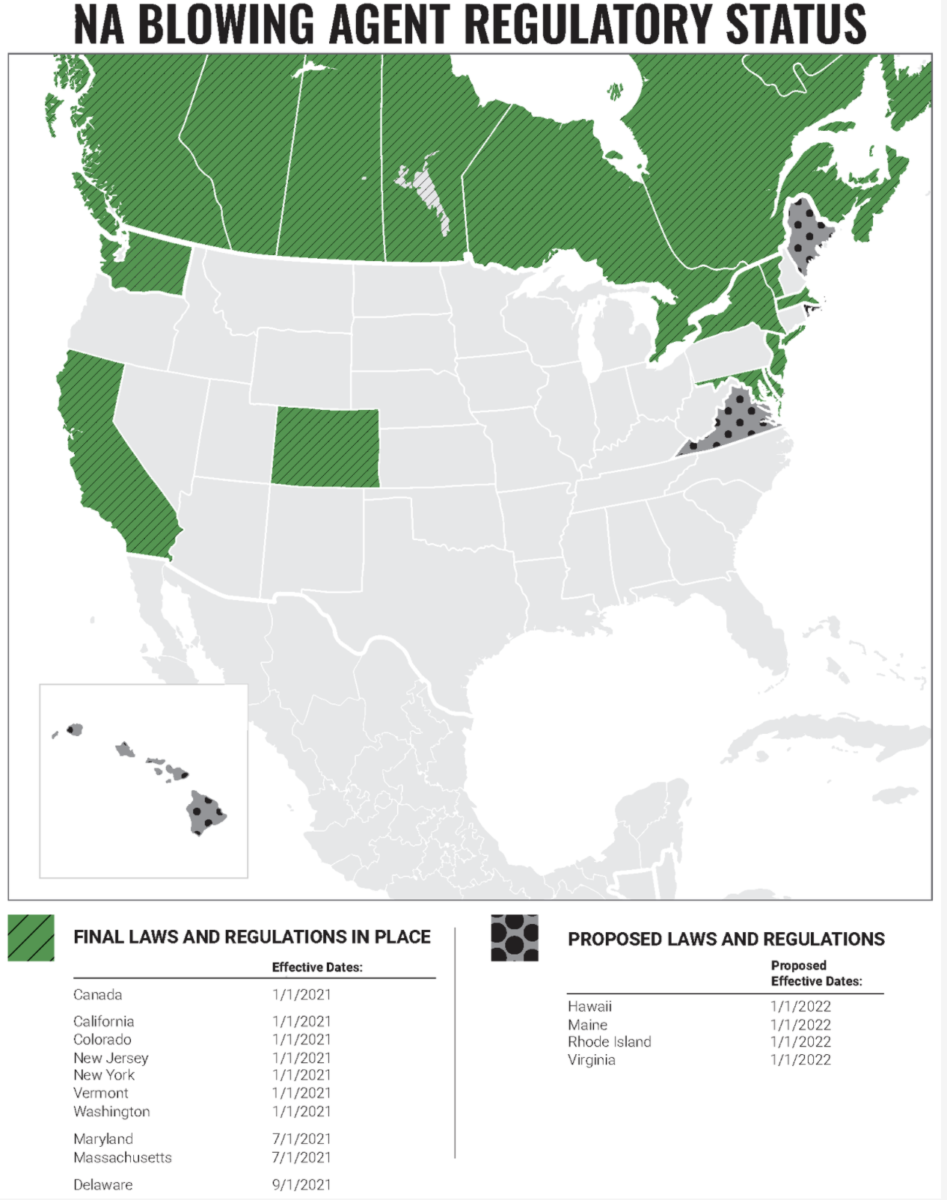

In just this manner, environmental regulations regarding the production and use of extruded polystyrene insulation blowing agents have come into effect in both Canada and parts of the United States. The patchwork application of environmental regulations that started earlier this year brings challenges for contractors and designers seeking to adhere to the new rules.

On January 1, 2021, regulations intended to lower the global warming potential (GWP) of building and roofing materials including the blowing agents used in extruded polystyrene insulation, took effect in Canada and several states — California, Colorado, New Jersey, New York, Vermont and Washington. Similar regulations in Maryland and Massachusetts started July 1 and more regulations are set to take effect in in several states in the next six months.

The new rules were not a surprise to many in the manufacturing space — including Owens Corning. When the new rules became effective on January 1, the company was ready to supply next generation extruded (NGX) rigid insulation — FOAMULAR NGX. The insulation, and the blowing agent used in its production, meets, or surpasses the revamped requirements. The product cuts the use of hydrofluorocarbon 134a in the blowing agent and lowers the insulation’s overall global warming potential. How much of a reduction in GWP? The new insulation reduces GWP by 90% compared to legacy FOAMULAR insulation production. But as any contractor knows, a material is only as good as its performance attributes. In that respect FOAMULAR NGX insulation maintains the high R-value per inch, high compressive strength and easy handling on the jobsite that have made XPS a go-to material for high-performing roofs. Even the color stayed the same. The insulation’s signature pink color is still easy to find at the supply house.

Designing Insulation to Meet New Rules

The need to change the blowing agent used in extruded polystyrene insulation was something that became apparent several years ago following proposed regulatory change in Canada.

Owens Corning’s R&D team started work on reformulating the product more than six years ago. While the legacy product already had a very low global potential compared to other products in the market, the new regulations challenged the development team to raise the stakes and really see how much of a reduction in GWP could be achieved.

Reformulating XPS insulation to become FOAMULAR NGX insulation took almost seven years of research as company polymer scientists worked through more than 100 blowing agent formulations.

While the regulations changed “overnight” on January 1, the new material and the attention paid to assuring its availability in both regulated and unregulated states was the result of years of planning.

How Low Can You Go … and Still Perform?

A goal of the revision process was not just to lower the GWP but to lower it and maintain all other elements of the insulation’s performance. It was anticipated that there could be concerns about the material’s attributes and handling if the blowing agent was changed, because of the important role that a blowing agent plays with insulation. Blowing agents are used to improve the thermal performance of insulations and help provide a targeted density. Along with the production process, blowing agents remain an essential ingredient in the “recipe” for producing extruded polystyrene foam insulation.

By maintaining performance elements from the original insulation, contractors and designers have a straightforward process to switch to the low-GWP formulation. Summed up as “the same, but more sustainable,” the only difference between legacy FOAMULAR XPS and FOAMULAR NGX is the lower global warming potential in this product.

The new offering is still able to manage loads up to 100 psi, has low water absorption potential enabling it to retain R-value when water is present, and the material provides a high R-value per inch. It also comes with a limited lifetime warranty on R-value performance, establishing that the insulation will maintain at least 90% of the R-value for the life of the product. Additionally, the insulation can be used with the same accessories.

When installing the new product, contractors use the same fasteners and same adhesives. The material cuts the same, and is measured and installed exactly the same.

The familiarity of this new material’s performance and handling profile helps it meet another critical objective, at a time when the labor crew is stretched and the construction sector is robust. Contractors can switch to the new material without having to retrain team members on its performance.

Environmental Recognition and Incentives

In addition to meeting new regulatory requirements, FOAMULAR NGX provides architects and building owners with a new tool when seeking to achieve aggressive sustainability goals. The material is manufactured using 100% wind energy and includes at least 20% recycled polystyrene, certified by Scientific Certification Systems. The insulation also is GREENGUARD Gold certified as reusable.

In addition to having a low GWP and being formulated without the use of HFC 134a in the blowing agent, the Insulation provides a more than 80% reduction in total product embodied carbon. The savings from reduced carbon dioxide emissions from installing 10 insulation boards equate to removing one car from the road for a year. Additionally, the reduction in GWP qualifies FOAMULAR NGX use as 1.5 products towards LEED 4.1 points for Options 1 and 2. Overall, using the material can help a project reach LEED, ENERGY STAR and National Green Building Standard ICC 700-2008 certifications.

Architects focused on the environmental effects of buildings will find the new material for vegetative roof assemblies and plaza decks to help manage storm water and meet more stringent codes regarding its runoff into waterway systems.

Kudos From the Manufacturing Leadership Council

Although rolled out to the market in 2021, the next generation material has already received industry honors. Owens Corning was awarded a 2021 Manufacturing Leadership Award from the Manufacturing Leadership Council for achievements in material science innovation intended to support environmental sustainability.

The company was named a “high achiever” having received the highest score among awardees in the “sustainability Leadership” category. The Council said the creation of FOAMULAR NGX was a demonstration of how leadership can support sustainable manufacturing because the insulation showed that companies can help protect the climate, limit embodied carbon, and improve sustainability while maintaining a high level of performance.

“Moving beyond complying with regulations and codes, we’ve found that sustainably-minded architects have a fierce interest in creating more sustainable buildings, and our products have an important role in meeting their needs,” said Frank O’Brien-Bernini, senior vice president and chief sustainability officer at Owens Corning.

About the author: Tiffany Coppock, AIA, NCARB, CDT, LEED AP, is the commercial building systems specialist at Owens Corning. Tiffany provides leadership in building science, system development, testing, and documentation. She can be reached via e-mail at [email protected].

References:

1. EPA Greenhouse Gas Equivalencies Calculator: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

2. FOAMULAR & FOAMULAR NGX Lifetime Limited Warranty (Pub No. 10015916)

For more on the subject, check out Roofing: The Industry’s Voice Podcast, Episode 3: “Coping With Environmental Regulations”

Chris King, editor of Roofing, caught up with Tiffany Coppock of Owens Corning at the 2021 International Roofing Expo to talk about ongoing changes in environmental regulations in the United States and Canada that greatly impacted the use of blowing agents in the reduction of global warming potential (GWP) — and how they are affecting manufacturers and contractors.

Episode 3, “Coping With Environmental Regulations,” is now available at www.roofingmagazine.com/podcasts.

Be the first to comment on "Environmental Regulations: 51 Potential Regulations – One Insulation to Comply and Perform"