Selecting the right components for a project can dramatically improve the performance and longevity of the overall building. In a commercial roofing project, the chosen insulation and the installation technique are critical to a building’s resilience and thermal efficiency.

From a physics standpoint, energy flows from a region of high to low potential (from warm to cold). Therefore, a significant amount of heat can leave a building through an inadequately insulated roof assembly during heating season (winter) and enter a building through an inadequately insulated roof assembly during cooling season (summer). A building with an under-insulated roof assembly may require more energy to compensate for these heat gains and losses.

The benefits of installing multiple, staggered layers of rigid board insulation have been well known for years. Industry authorities, including National Roofing Contractors Association (NRCA), Oak Ridge National Laboratory (ORNL), Canadian Roofing Contractor Association (CRCA) and International Institute of Building Enclosure Consultants (IIBEC), formerly RCI, Inc., have recognized these benefits; and contractors, designers and specifiers have followed the roofing industry’s long-standing recommendation for the installation of staggered insulation layers.

Using the optimal roof insulation product also will impact performance. Polyiso insulation offers key advantages in meeting stricter building standards and improving energy efficiency. Polyiso has a high design R-value compared to XPS, EPS, and mineral wool board. Lightweight and easy to trim, polyiso can be layered to reach the desired R-values without being cumbersome to install.

Why Are Multiple, Staggered Layers of Insulation Important?

In 2015, the International Energy Conservation Code (IECC) increased the R-value requirements for the opaque thermal envelope in many climate zones across the United States. As a practical matter, most roofs will require two or more layers of insulation to meet the local energy code requirements. In the 2018 version, the IECC was updated with specific installation requirements for continuous roof insulation. The 2018 IECC explicitly calls for continuous insulation board to be installed “in not less than 2 layers and the edge joints between each layer of insulation shall be staggered” (Section C402.2.1 Roof assembly).

Staggering the joints of continuous insulation layers offer a number of benefits:

· Increased thermal performance/reduced thermal loss: The staggered joints on multiple layers of insulation offset gaps where heat could flow between adjacent boards. The staggered approach to installing insulation reduces thermal bridging in the roof assembly. A fact sheet on roof insulation published by Johns Manville (RS-7386) notes that as much as 8 percent of the thermal efficiency of insulation can be lost through the joints and exposed fasteners of installations that use only a single layer of insulation.

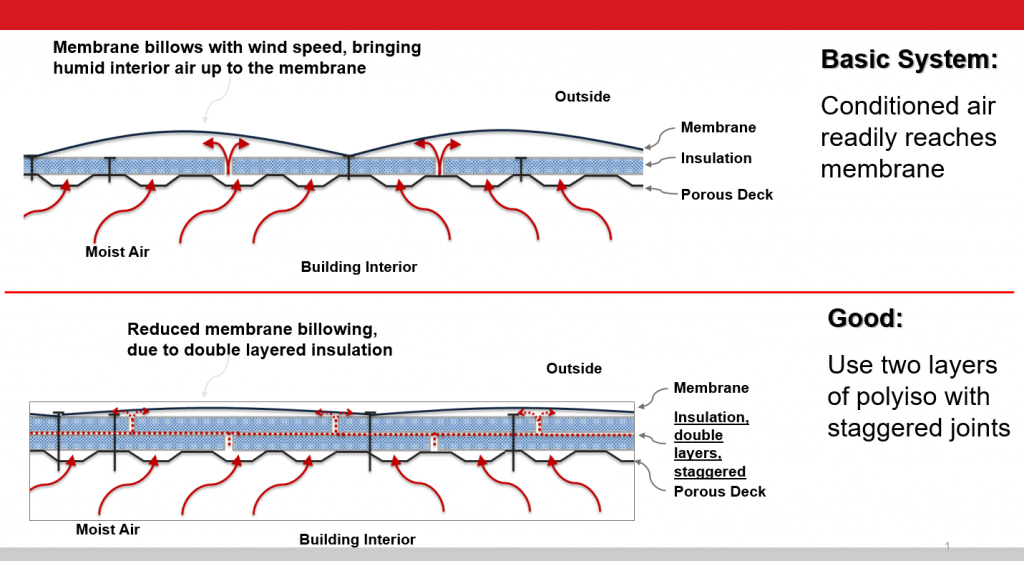

· Air intrusion: When conditioned air enters the building envelope, often because of pressure gradients, it carries moisture into the roofing system. This moisture will undermine optimal performance. A peer-reviewed study on air intrusion impacts in seam-fastened mechanically attached roofing systems showed that air intrusion was minimized by nearly 60 percent when the insulation joints were staggered between multiple layers of insulation. (See “Air Intrusion Impacts in Seam-Fastened, Mechanically Attached Roofing Systems,” by By Suda Molleti, PEng; Bas Baskaran, PEng; and Pascal Beaulieu, www.iibec.org.)

Additionally, by limiting the flow of air and moisture through a roof system, staggered layers of insulation in a roof assembly can reduce and/or prevent condensation. The condensed moisture if allowed to remain and accumulate in the system can damage the substrate and potentially shorten the service life of a roof. A properly insulated roof can also prevent the onset of condensation by effectively managing the dew-point within the roof assembly.

· Resilient roof assemblies: Staggered joints can reduce the stress put on a single insulation layer and distribute that stress more evenly over multiple, thinner insulation joints. For example, in an adhered roof system, the installation of multiple layers of insulation can minimize the potential for membrane splitting. In this system, the upper layer(s) of insulation can protect the membrane from potential physical damage caused by fasteners that are used to attach the bottom layer of insulation to the roof deck.

· Ponding water: Roof slope is often created through the use of tapered insulation systems. These systems offer an opportunity to stagger the joints by offsetting insulation layers and improve overall energy performance of a system. If the added insulation layer is tapered, the slope provided can improve drainage performance of the roof. Rainwater that does not drain and remains standing, collects dirt and debris that can damage or accelerate erosion of roof covering. Integrating tapered polyiso system with staggered joints into a roof’s design will not only improve the thermal performance but also can improve drainage and thus overall longevity of the system.

· Puncture resistance: Roof cover boards are commonly installed to provide a suitable substrate for membrane attachment as well as protect the roof assembly from puncture and foot traffic. When using products like polyiso high-density roof cover boards, the joints should also be staggered with the underlying roof insulation. This ensures the benefits discussed above are preserved in systems utilizing cover boards.

Installation Best Practices Are Keys For Success

A properly designed roof system that utilizes high-performance polyiso insulation products is a strong foundation (or cover) for energy-efficient and sustainable construction. However, the designed performance can only be achieved through proper installation. Implementing industry best practices such as the installation of multiple layers with staggered joints will optimize energy efficiency of the system and will help ensure that the roof system performs during its service life.

To learn more about the benefits and uses of polyiso insulation,please visit the Polyisocyanurate Insulation Manufacturers Association website at www.polyiso.org.

About the author: Marcin Pazera, Ph.D., is the Technical Director for Polyisocyanurate Insulation Manufacturers Association (PIMA). He coordinates all technical-related activities at PIMA and serves as the primary technical liaison to organizations involved in the development of building standards. For more information, visit www.polyiso.org.

Be the first to comment on "Improve Commercial Roof Performance With Staggered Insulation Layers"