Innovation Amphitheater is a 1,500-seat arena in Barrow County, Georgia. The striking curved, clamshell-style roof above the outdoor stage looks across the complex at the building that houses the ticket office and concession stand. Both are clad in matching charcoal-colored standing seam metal roof systems.

SACO Systems installed approximately 12,000 square feet of Petersen’s PAC-CLAD 24-gauge Tite-Loc Plus panels on the amphitheater roof and 10,000 square feet of the company’s Snap-Clad panels on the amenities building.

“The roof on the concession and restroom building was a 6:12 slope with hips and ridges,” notes John Salo, vice president of SACO Systems. “The stage roof was literally curved with the panels sloping from the front to the back and draining to the rear of the stage.”

Founded in 1976, SACO Systems focuses on architectural metal cladding components for roofs and walls, as well as custom canopies and awnings. The company was called in on the Innovation Amphitheater project by Carroll Daniel Construction, the construction manager, and asked to provide pricing for the project.

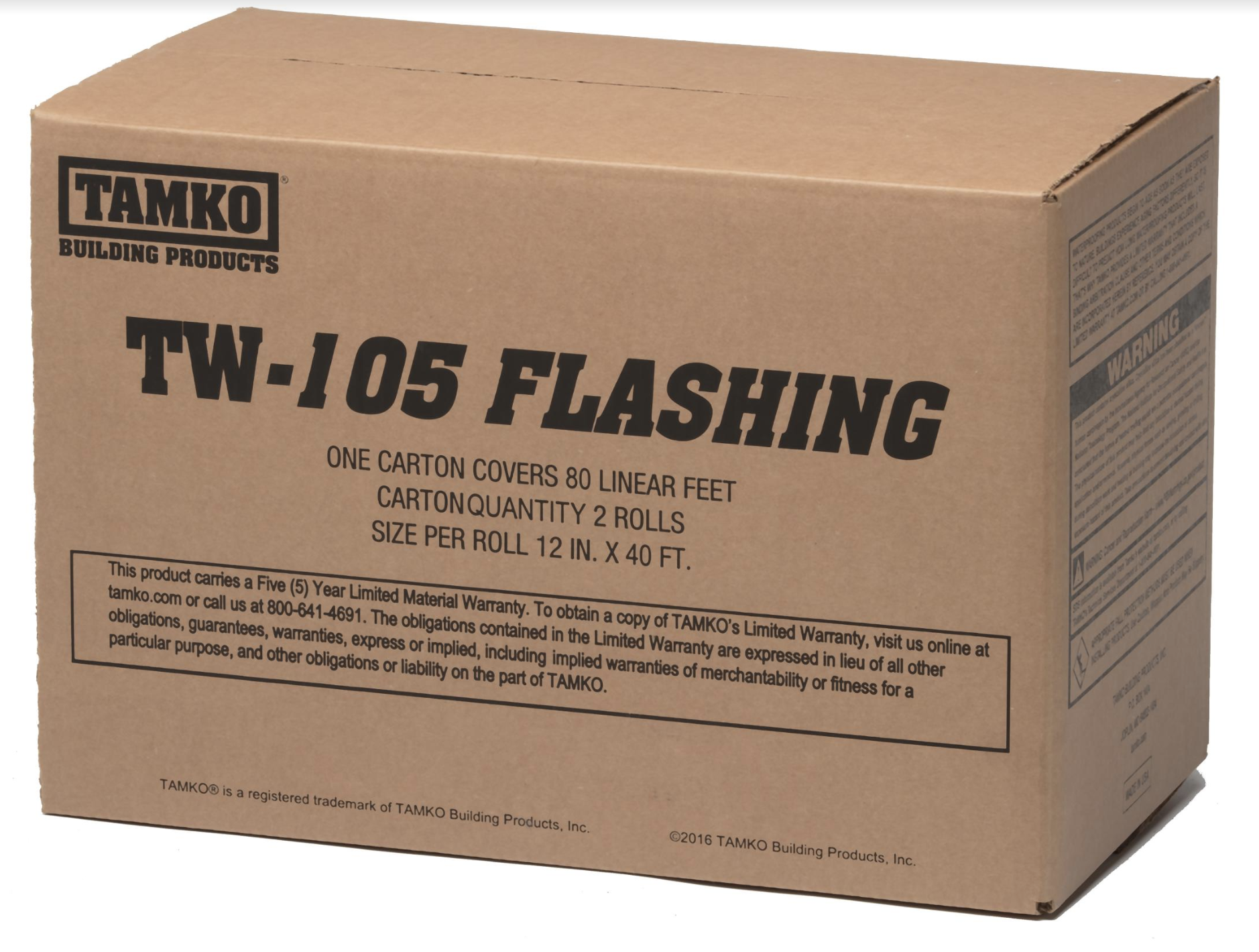

Both roof systems were installed over metal decks and featured Atlas AC Foam II polyiso insulation and TAMKO TW Metal and Tile self-adhered, waterproofing underlayment. “Given the compounding slope of the stage roof, the mechanically seamed panels were an ideal choice for the project,” Salo states.

The Installation Process

After the metal decking was installed and inspected, crews from SACO Systems mobilized at the site. “We field measured for the PAC-CLAD panels and coil stock to fabricate the trims and flashings required for the project,” notes Salo. “We installed the insulation and underlayment to dry in the structure prior to panel delivery. We returned to the site a few days prior to panel delivery and began installing perimeter flashings that were fabricated in our facility in preparation for the panel installation.”

Executing the curved design of the amphitheater roof in the field would be the biggest challenge on the project. Salo contacted Dave Landis, Petersen’s sales and technical services manager for the Southeast. He’s often called in to consult on complex jobs and approves warranty applications.

Constructing a perfectly symmetrical curved roof is a difficult task, and in this case, the task was made even more difficult by the way the panels were oriented on the roof. “In this case, the panels ran parallel to the curve,” notes Landis. “Typically, they run perpendicular to the curve. Any time we deal with curved roofs on a building, there are always some imperfections in the structural decking and the structure of the building, and the roofer and the general contractor must give their best efforts to try and get it within reasonable plumbness so that we can get a roof cladding to lay down and look good.”

After walking the roof with the superintendent, Landis and the SACO Systems team developed an ingenious method of achieving the nice, smooth curve that was desired. “What we ended up doing was using two different types of clips to account for the imperfections in the deck,” Landis says. “We used flat clips that pull the panel flush to the deck, and we interspersed those with 3/8 space clips, which lift the panel up 3/8 of an inch off the deck. We used the clips to account for the more challenging areas where the curve wasn’t perfect. The clips made it work.”

Compared to the amphitheater roof, the other roof sections, including the small shed roofs off to the side of the theater, were pretty straightforward. “The roof on the amenities building was pretty cut and dried,” says Landis.

A detailed safety plan was essential, and crews used retractable roof anchors and personal fall arrest systems with double lanyards. “Fall protection is routinely our greatest concern on these projects,” says Salo.

Salo credits teamwork for the project’s successful execution. “This project was able to showcase what we consider one of our greatest assets: the relationships we have built with other companies like the construction manager and PAC-CLAD,” concludes Salo. “We were able to install a first-class roofing system that will perform for the owner for many years to come and at the same time find a solution to match the original design intent despite challenges along the way.”

TEAM

Architect: Lindsay Pope Brayfield & Associates, Lawrenceville, Georgia, www.lpbatlanta.com

Construction Manager: Carroll Daniel Construction, Gainesville, Georgia, www.carrolldaniel.com

Roofing Contractor: SACO Systems, Suwanee, Georgia, http://sacosystems.com

MATERIALS

Metal Panels: PAC-CLAD 24-gauge Tite-Loc Plus and Snap-Clad, Petersen, www.pac-clad.com

Underlayment: TW Metal and Tile, TAMKO, www.tamko.com

Insulation: Atlas AC Foam II, Atlas Roofing Corporation, www.atlasrwi.com

Be the first to comment on "Innovative Design Comes to Life at Innovation Amphitheater"