Because Rich-E-Board roofing insulation is light and easy to install, it lowers the cost of delivery and handling and can reduce labor costs by more than half.

owners, contractors and architects seeking to drive down construction costs and boost energy efficiency.

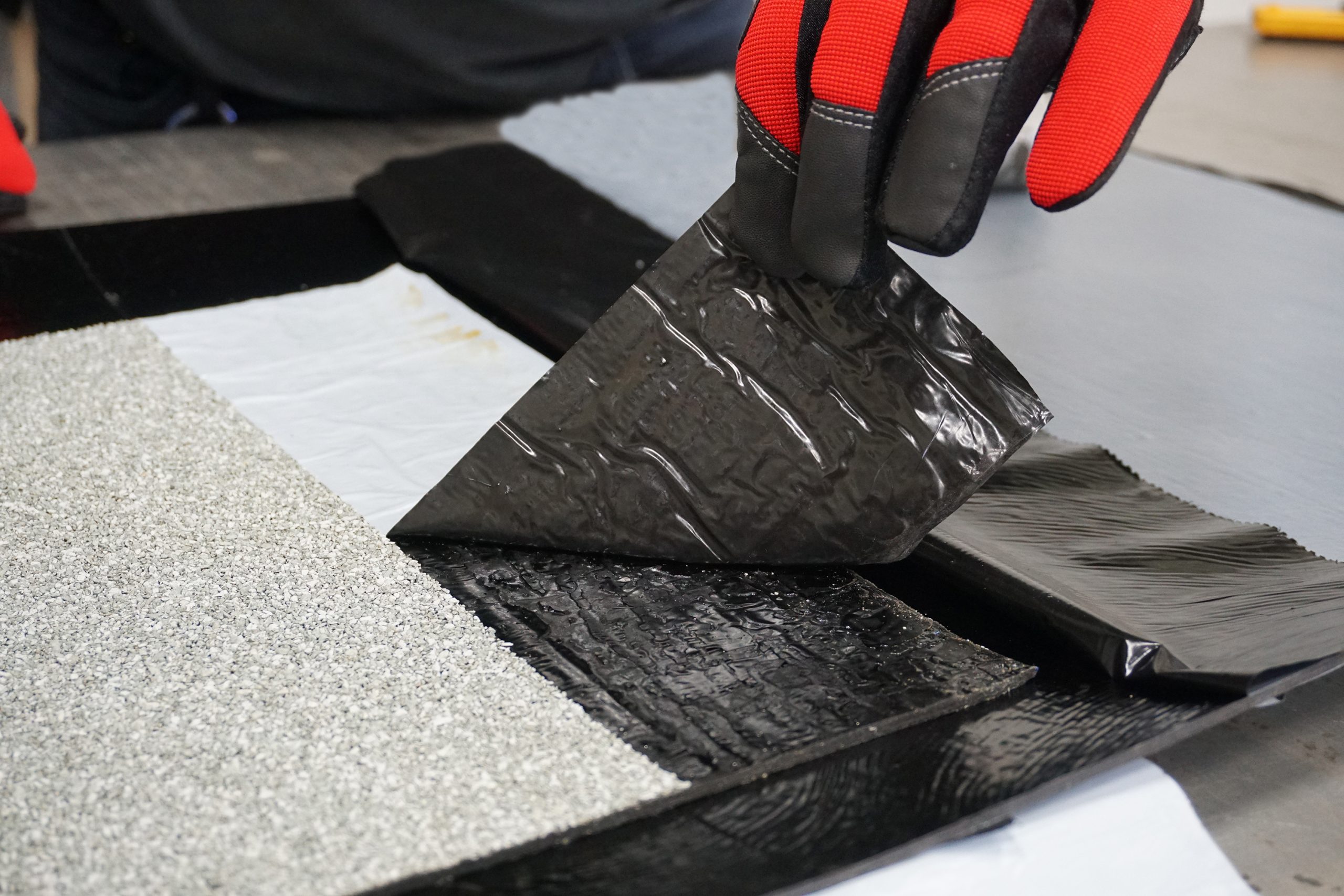

Rich-E-Board recently received a patent for its proprietary Vacuum Insulated Panel—two polymeric foam cover boards that sandwich the panel—and the adhesive ribbons that bind the boards and panel together. This ultra-thin insulation offers a certified alternative to a huge commercial roofing market—billions of square feet in construction every year—challenged with

meeting stringent standards for energy efficiency.

While conventional insulation requires a thickness of 15 inches to reach an R-value of 50, Rich-E-Board achieves the same result at just 1.5 inches thick. Rich-E-Board can be installed on most roof deck types, including ballasted roof systems, and can support all conventional low-slope roof systems.

Rich-E-Board’s design delivers significant advantages:

- Lower energy bills: Achieving an R-value of 50 can cut a building’s heating and cooling costs by 8 to 10 percent, according to the GSA.

- Simpler retrofits: Rich-E-Board enables retrofitted structures to achieve required R-values in less time, with fewer materials, and without costly and destructive building modifications.

- Reduced construction costs: Because Rich-E-Board is light and easy to install, it lowers the cost of delivery and handling and can reduce labor costs by more than half.

- Design flexibility: With its slim profile— especially compared with multi-layer insulation— Rich-E-Board saves space, expanding the design options for architects.

Rich-E-Board is also fireproof and water and mold resistant, notes Joanne Collins, president and CEO of R-50 Systems, maker of Rich-EBoard. “Our team focused on creating a game-changing alternative,” Collins says. “Rich-E-Board fills a significant

void in the marketplace by providing an insulation system capable of meeting today’s tougher energy standards.”

Success in the Field

Rich-E-Board has made a successful transition from the drawing board to the marketplace. Owners and architects have taken advantage of the insulation’s slim profile and high R-value on several building projects.

At a government building in Chicago, for example, owners chose to install 3,600 square-feet of Rich-E-Board as part of a roof retrofit aimed at lowering lifetime energy costs. Rich-E-Board’s slim profile also cut construction costs by more than $20,000 by streamlining design and installation.

At the Cohen Courthouse in Camden, N.J., Rich-E-Board was selected for the roof retrofit, eliminating the need for expensive building modifications that would have been required for conventional insulation. The decision lowered the project cost by $200,000.

Earlier this year, Rich-E-Board was awarded a patent for its design. More recently, the insulation earned its first LEED 4 designation.

“We’re seeing a huge increase in Rich-E-Board as the roofing market learns more about the benefits it brings to the commercial roofing,” Collins says. “This product fills a significant void by providing an insulation system capable

of meeting today’s tougher energy standards.”

Collins notes that, in addition to the $5 billion annual market for commercial roofing, Rich-E-Board can be used in walls and other building applications. Rich-E-Board is 99 percent recyclable and made entirely in the U.S.

PHOTOS: R-50 SYSTEMS

Be the first to comment on "Innovative Roofing Insulation Appeals to Owners, Architects"