“Lean Construction extends from the objectives of a Lean production system — maximize value and minimize waste — to specific techniques, and applies them in a new project delivery process.”

- Lean Construction Institute

The effectiveness of the labor hour has not improved in the last 50 years, according to the Lean Construction Institute. I can attest to this, as the process of replacing roofs has changed little in the 35 years I have been observing them being installed. The method seems to be to just throw crews at the project and hope the bottom line works out. While we have new materials, larger projects and unique ways to reroof, it appears the solution is always the same: Throw crews at it and hope the bottom line works out.

I have long wondered why the work wasn’t planned better. I know management. “Mgmt” is a four-letter word. Why not raise the roof edge prior to removing the old roof (when feasible)? Why not remove the abandoned roof curbs and “deck it in” or raise the roof curbs, add pipe curbs, install new or replacement roof drains all before removing the roof?

I hear it again and again: “We’ll do it when we get there.” So, I often find myself watching as a few crews try to raise the roof edge and get it completed prior to the new roof installation. This is especially challenging at corner conditions when there is considerable roof edge. What often happens is that the roofing catches up to the wood blocking, and time is wasted waiting for the wood blocking to be completed. As an observer and one always trying to slim down the process, I’ve often thought that a well-managed project would render enormous benefit. Isn’t effective, efficient project management even more important today, as labor shortages have significantly reduced available labor?

Opportunity to Change

Timing is often a catalyst for change. With the recent material shortages, now might be the time to review how projects are completed. (Don’t get me started on my views about material shortages. Manufacturers didn’t plan for an inevitable event, don’t plan as needed for the summer season, and still make insulation of every conceivable thickness. How about getting rid of most of those thicknesses and go with only half-inch increments? Now there is a novel thought: Simplify. Now, I know if you’re a supplier you are thinking I need the 1.1 inch so the contractor can meet a code required R-Value. Well, let’s start with acknowledging that delivered to the site, insulation boards’ thickness does not match that which was specified [allowable by the ASTM Standard] and that code is the minimum; you can go thicker. “Oh, but the other suppliers will get the job if I don’t have that thickness.” Perhaps so, but I think if you can get the material out quicker and have it when needed, things will change. I digress, but at least I got that off my chest.)

I have several projects that are large or complex or both — projects that require a great deal of man-hours. Insulation is weeks, if not months, away, and roofing contractors are fearful that they will not have enough work to keep their crews busy. And then what happens when the dam breaks and materials flow — will enough workers be available to complete the projects?

How can contractors attain a win – win? I believe the answer lies in Lean Thinking: shortening and managing the process.

How to Shrink the Process

Let’s review one of my projects currently underway and being managed by Jason Tenpas, Senior Project Manager for All American Exterior Solutions: Replacing an aged, ballasted EPDM roof on a school building. Roofing materials are scheduled to arrive in late July, with a substantial completion date of August 15, 2021, and liquidated damages of $3,500. First, let’s review the plans and details to understand all the work that is required and see what if any of that work could be completed before the insulation and membrane arrives.

This review revealed the following potential items for early installation:

1. Raising of the roof edge.

2. Raising of roof curbs.

3. Installation of new pipe curbs.

4. Insulating a roof side mansard installed to cover structural bracing.

5. Masonry restoration of split face concrete block.

6. Removal of a gas pipe.

7. Installation of new pipe curbs.

8. Removal of an air-handling unit and installation of a curb extension.

9. Roof drain renovation.

10. Raising of plumbing vents.

Of these, the contractor determined that items 1-8 were feasible. Items 9 and 10 could not be completed before the roof system installation begins, as the roof drain renovation will involve re-leading the joints after the ballast is removed and raising of the plumbing vents would inhibit the installation of the new 90-mil EPDM.

The goal is to have the first eight items above completed so that when material arrives, re-roofing can move forward at rapid pace.

Implementing the Lean

The project manager from the contractor is excellent and thought this through.

The skylight glass replacement, in which the replacement glass was ordered within days of project award, was ready for delivery the first week after the school year ended. As the skylight glass work, masonry restoration and mansard insulation are stand-alone work, they were scheduled to start the first week after school is out. This allows those contractors, pipe scaffolding, and roof protection to be off the roof and out of the way when the roofing work begins.

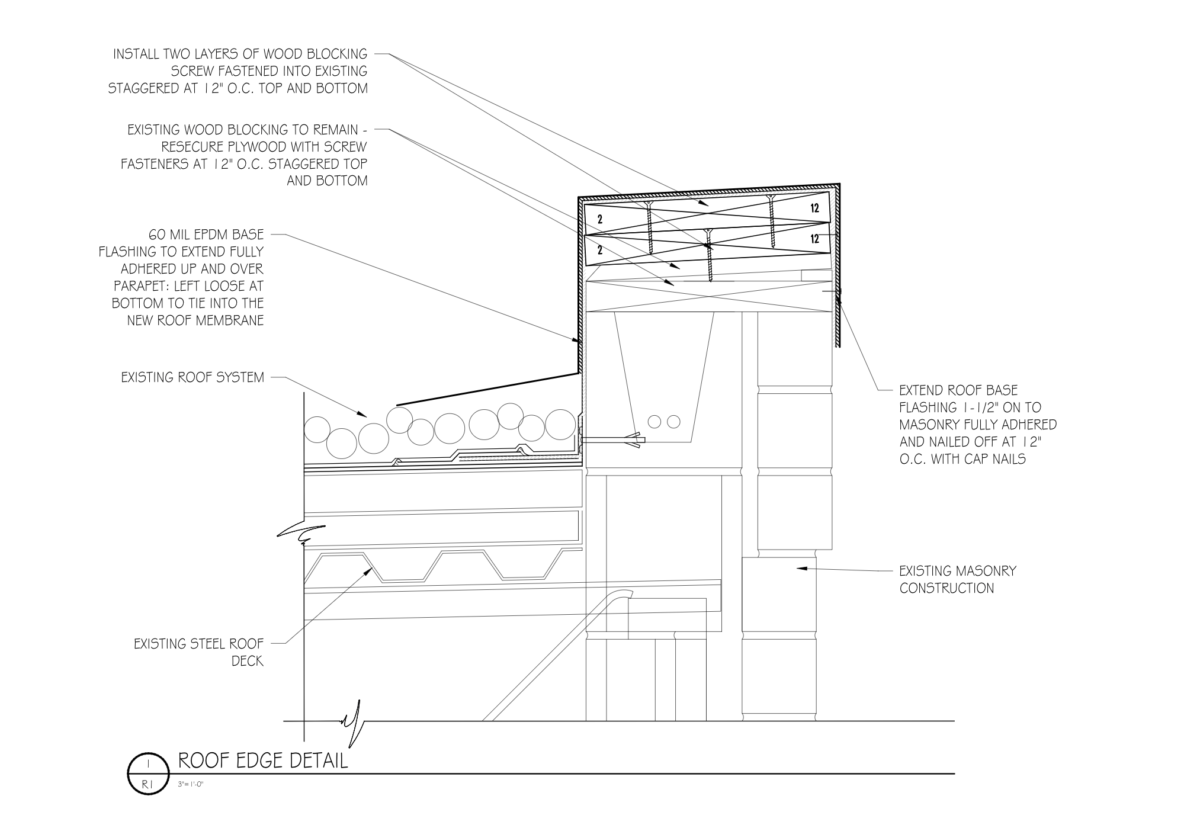

At the roof edge, the sheet metal was removed, the existing EPDM that was brought up and over the parapet was allowed to remain, and new wood was installed. This change is reflected in Figure 1. Now, here is the big lead item: The wood blocking was immediately covered with 60-mil EPDM flashing, which is the finished flashing to which the new roofing will be integrated. With the roof edge complete, sheet metal can now also be fabricated and installed prior to the arrival of the insulation. How about that — the sheet metal can be installed before the roofing!

The gas pipe was disconnected and moved.

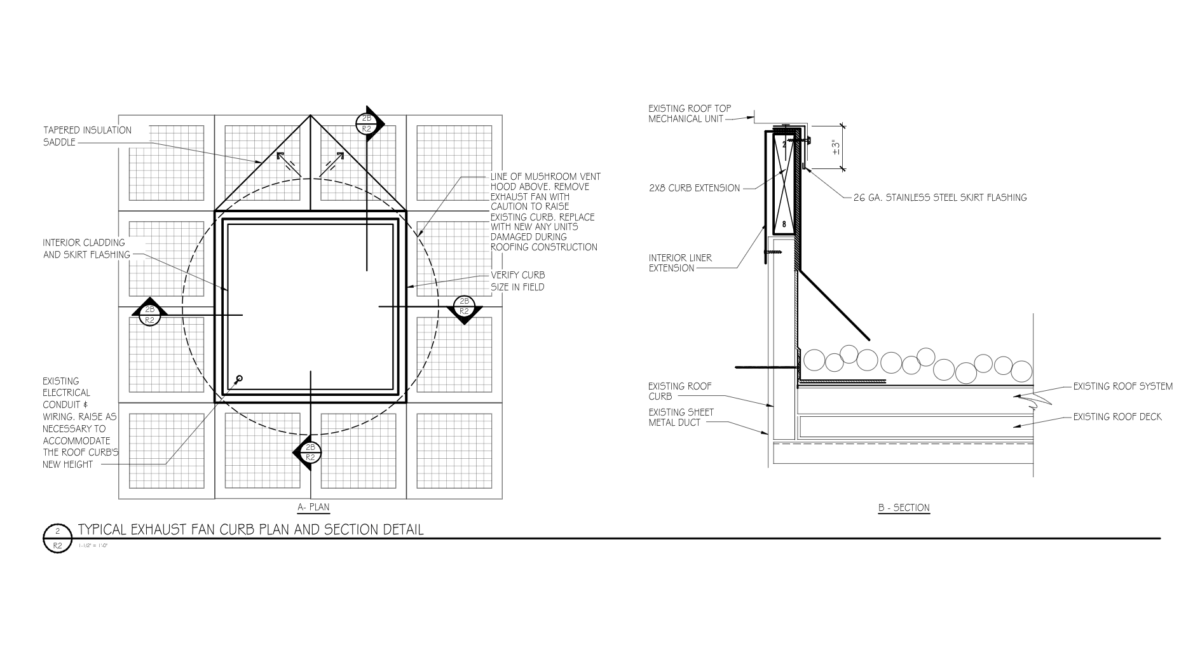

Plans called for the roof curbs to be raised, so the mechanical unit was removed, the curb raised, and the EPDM base flashing installed on the new blocking with a portion loose over the existing base flashing to be integrated later with the main roof membrane. The protective stainless steel skirt flashing was installed and the mechanical unit was re-set.

The roof insulation is slated to arrive at the end of July. The project was managed so that even with an extremely late delivery of materials, the project will be completed before the substantial completion date and associated liquidated damages.

Always Improving

Our office motto is Kaizen — “continuous improvement” — in all aspects.

I challenge both designer and contractor to determine what can be changed to save time and increase productivity.

Einstein said doing the same thing over and over again and expecting a different result was the definition of insanity. Thirty-five years of the same thing has to qualify.

And Bernard Shaw wrote: “The reasonable man adapts himself to the world: the unreasonable one persists in trying to adapt the world to himself. Therefore, all progress depends on the unreasonable man.”

Those who adapt to the new normal and become “the unreasonable man” will survive and prosper. Will that be you?

About the author: Thomas W. Hutchinson, AIA, CSI, Fellow-IIBEC, RRC, is a principal of Hutchinson Design Group Ltd. in Barrington, Illinois. For more information about the company, visit hutchinsondesigngroup.com.

Be the first to comment on "Labor and Material Shortages Make Project Management More Important Than Ever"