There are two typical pathways for demonstrating compliance with building energy codes — a prescriptive compliance pathway that establishes specific minimum acceptable standards for individual building elements and a performance-based compliance pathway that establishes an overall energy target for the entire structure. The latter approach allows design professionals to trade-off elements against one another to achieve code compliance. While both approaches have their merits, relying on prescriptive requirements is typical for roof renovation or roof replacement projects in existing buildings, and provides assurance that no compromises are made in a building’s energy efficiency for critical areas like the building envelope. Heat transfer through the roof assembly can significantly undermine the building’s energy efficiency and this is more pronounced in lower-story structures with large roof footprints. Since re-roofing activity may occur several times during the full-service life of a building, complying with prescriptive R-value requirements under the applicable energy code offers an opportunity to improve the building’s energy efficiency performance.

The minimum prescriptive requirements applicable to above-deck insulation for commercial roofs in the United States typically range from R-20 in warmer climate zones to greater than R-40 in colder climate zones. Specific to the United States, the International Energy Conservation Code (IECC) includes prescriptive R-value requirements for roof insulation located entirely above the roof deck (IEAD). The total R-value is based on all installed layers of insulation.

Polyiso is a versatile roof insulation option that is manufactured in a wide range of incremental thicknesses from 0.5-inch to 4.5-inch and in various slopes with tapered insulation systems. This versatility allows design professionals to meet the required R-values and provide the project with improved performance in other areas such as increased roof drainage and reduced installation labor. Construction professionals should consult individual polyiso manufacturers for product-specific information like available thicknesses and R-values.

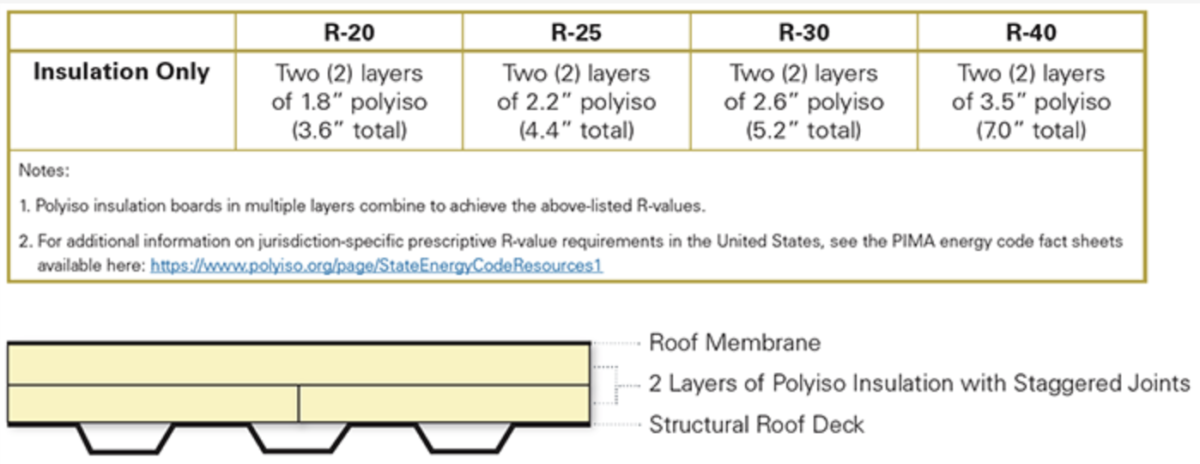

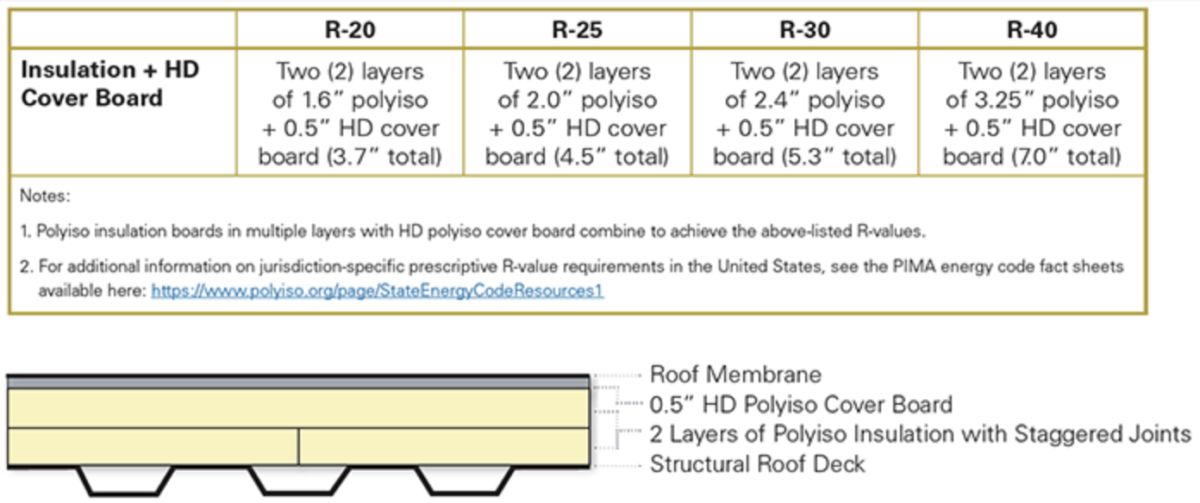

The examples below provide various, multi-layered configurations for polyiso roof insulation that satisfy minimum R-value requirements ranging from R-20 to R-40. This range of R-values represents typical minimum requirements for the majority of climate zones in the United States. These examples are common for new and replacement roof project specifications. Polyiso roof insulation boards in various thicknesses can be combined to address project requirements that exceed R-40.

Example 1: Recommended Polyiso Roof Insulation Thicknesses for Meeting Commercial Prescriptive R-Value Requirements.

Example 2: Recommended Polyiso Roof Insulation Thicknesses with HD Polyiso Cover Board for Meeting Commercial Prescriptive R-value Requirements.

The high R-value and light weight of high-density (HD) polyiso cover boards provide important contributions to the design of a durable roof system. A typical 0.5-inch HD polyiso cover board adds R-2.5 to the total R-value of the roof insulation system.

Proper Installation With Staggered Joints

Under the IECC, continuous roof insulation is generally required to be installed in two or more layers with staggered edge joints (see C402.2.1). Furthermore, the practice of installing multiple, staggered layers of rigid board roof insulation has well-documented benefits. Trusted industry authorities, including National Roofing Contractors Association, Oak Ridge National Laboratory, Canadian Roofing Contractors Association and International Institute of Building Enclosure Consultants, all recognize these benefits in their best practice literature, which is based on rigorous testing and research.

Given the minimum code requirements for insulation across all compliance pathways and industry best practices, all roof system designs for new and replacement roofs should incorporate a multi-layered, staggered joint continuous insulation system.

Staggering the joints of continuous insulation layers in roof systems offers the following benefits:

• Increased thermal performance/reduced thermal loss: Staggering the joints on multiple layers of insulation offsets gaps where heat could flow between adjacent boards. This staggered approach to installing insulation reduces thermal bridging in the roof assembly.

• Air intrusion: A peer-reviewed study on air intrusion impacts in seam-fastened mechanically-attached roofing systems showed that air intrusion was minimized by nearly 60 percent when the insulation joints were staggered between multiple layers of insulation.1

• Resilient roof assemblies: Staggered joints can reduce the stress put on a single insulation layer and distribute that stress more evenly over multiple, thinner insulation joints. 2

• Tapered insulation considerations: Roof slope is often created through the use of tapered insulation systems to reduce or eliminate ponding water. These systems offer an opportunity to stagger the joints by offsetting insulation layers to improve overall energy performance of a system. If the added insulation layer is tapered, the slope created can improve drainage performance of the roof. Integrating a tapered polyiso system with staggered joints into a roof’s design will not only improve its thermal performance but also can improve drainage and overall longevity of the entire roof.

• Roof cover board considerations: Roof cover boards are commonly installed to provide a suitable substrate for membrane attachment and to protect the roof assembly from puncture and foot traffic. When using products like polyiso high-density roof cover boards, staggering the cover board joints with the layers of underlying roof insulation ensures the benefits discussed above are preserved.

About the author: Marcin Pazera, Ph.D., is the Technical Director for Polyisocyanurate Insulation Manufacturers Association (PIMA). He coordinates all technical-related activities at PIMA and serves as the primary technical liaison to organizations involved in the development of building standards. Dr. Pazera holds a doctoral degree in mechanical engineering from Syracuse University and has worked in building science with a focus on evaluating energy and moisture performance of building materials and building enclosure systems. For more information about PIMA, visit polyiso.org.

End Notes:

1. https://rci-online.org/air-intrusion-impacts-seam-fastened-mechanically-attached-roofing-systems/

Be the first to comment on "Meeting Prescriptive Commercial Roof R-Value Requirements"