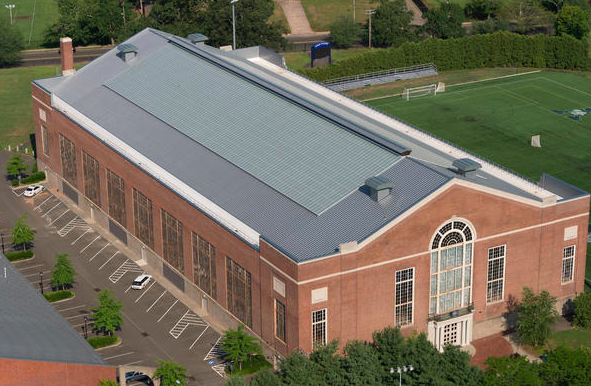

Vanderbilt University Recreation and Wellness Center, Nashville, Tenn.

The construction team chose Sika Sarnafil’s G410 felt back 60-mil PVC in light gray as the deck sheets and a custom color G410 bareback in dark gray to match the metal siding on the upper fins of the building’s east side.

TEAM

ROOFING CONTRACTOR: Professional Roofing Contractors Inc., Shelbyville, Tenn.

ARCHITECT: Moody Nolan, Nashville

GENERAL CONTRACTOR: American Constructors Inc., Nashville

ROOF MATERIALS

The construction team chose Sika Sarnafil’s G410 felt back 60-mil PVC in light gray as the deck sheets and a custom color G410 bareback in dark gray to match the metal siding on the upper fins of the building’s east side. The architects also wanted to use the Decor ribs at equal distances between the fins. The materials were chosen because of their reflectivity and their smoothness in appearance. The PVC also had the advantage of a lacquer-coated finish, which should help it stay cleaner; the 3 1/2:12 sloped surfaces will be seen from the street.

ROOF MANUFACTURER: Sika Sarnafil

ROOF REPORT

Professional Roofing Contractors worked closely with American Constructors’ Project Manager Andrew McAllister preparing preliminary budgets and system comparisons of cost and quality to meet the university’s budget constraints and quality requirements.

The sloped surfaces presented a challenge in stocking the materials on the roof and transporting half of the materials over the ridge.

The sloped surfaces presented a challenge in stocking the materials on the roof and transporting half of the materials over the ridge. The roofing crew built braces to keep the materials from sliding down the sloped metal decking. The crew could not reach the west side of the roof with the crane and had to hand carry materials over the ridge, which challenged the labor budget. Once materials were in place, installation went smoothly.

To provide for a safe work environment, Professional Roofing Contractors bought a new safety rail system to put at the lower edge of the sloped decks. The team prepared proposed loading diagrams for the material storage on the roof for the engineers’ approval and lifted all the materials on the east side of the roof in five staged deliveries with an 80-ton crane. The safety rails kept the roofing crew from having to be fully tied off and kept the job safe for the duration.

The large fins that extended onto the east side of the roof deck had to match the color of the vertical metal fins that went down the sides of the building. Professional Roofing Contractors did a sample fin for the contractor’s and architect’s approval. Everyone approved the mock-up and the roofing crew proceeded to do the rest of the fins.

Other challenges arose while matching metal fascia, coping, gutters and downspouts to the other metal-siding colors. With a few color runs, Professional Roofing Contractors was able to satisfy those requirements, as well.

With the assistance of its Sarnafil rep, Michael Johnson, and inspector, Brian Olsen, Professional Roofing Contractors completed the project on time and within budget to the full satisfaction of the construction manager, architects and owners. The superintendent, John Armour, noted Professional Roofing Contractors was his strongest sub on the job.

PHOTOS: PROFESSIONAL ROOFING CONTRACTORS

Be the first to comment on "Projects: Education"