Directly off the Massachusetts Turnpike and with easy access to the commuter rail, the newly developed Boston Landing community will be one of the most progressive and convenient living communities in the city of Boston. This community boasts numerous brand-name shops, restaurants, bars, residential facilities, and thousands of square feet of office space. While the community is designed to provide convenient shopping, eating, and socializing for its residents, perhaps the most unique, sought-after aspect of Boston Landing is its support of local sports teams. The community houses the Auerbach Center — the Boston Celtics’ new, 70,000-square-foot practice arena — as well as a practice arena for the Boston Bruins and the global headquarters for New Balance Athletics.

Construction on the Auerbach Center began in December 2017 and was completed in June of the following year. One of the primary aspects of this new construction project was the installation of the roofing system, which was managed by Peabody, Massachusetts-based

contractor Marshall Roofing and Sheet Metal Co., Inc.

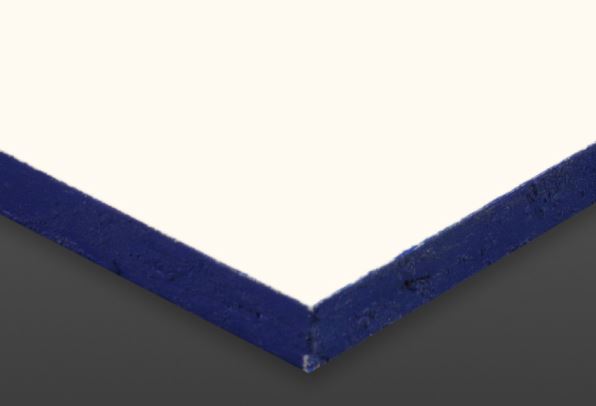

The team at Marshall Roofing and Sheet Metal chose to use a PVC roofing assembly manufactured by Carlisle SynTec Systems. Marshall Roofing has been installing Carlisle roofing membranes since 1989 and the team knew that the Sure-Flex PVC membrane would be ideal for this application due to its long-term durability, resistance to harsh weather conditions, and flexibility of installation. The team chose to use a combination of white and gray PVC membranes to complete this rooftop with a unique aesthetic appeal.

Topping the Practice Facility

The 58,000-square-foot rooftop of the practice facility presented a challenge that required four separate roofing system designs to cover multiple roof levels, all of which contained extensive HVAC equipment, dunnage posts, and screen wall assemblies. Carlisle’s 60-mil-thick Sure-Flex PVC membrane provided the flexibility needed for this type of rooftop challenge. The company’s PVC membranes incorporate a strong polyester reinforcement that enhances their durability — a durability that would be essential for the extreme temperatures and precipitation Boston often experiences during the winter months.

The installation of this complex rooftop system began with the rooftop decks. Of the four levels, two levels utilized a concrete deck and two utilized a steel deck. For the steel deck roofing assemblies, the crew from Marshall Roofing installed a 5⁄8-inch cover board, followed by the application of Carlisle’s VapAir Seal 725TR Temporary Roof and Air/Vapor Barrier membrane, which consists of 35 mils of self-adhering rubberized asphalt laminated to a 5-mil woven polypropylene film. The application of 725TR ensures that the roofing system maintains consistent air and vapor barrier priorities while also increasing its strength. Once the 725TR was applied, the crew installed 6 inches of Carlisle’s InsulBase polyiso insulation to increase the thermal efficiency and R-value of the roofing system.

After the insulation was in place, Carlisle’s half-inch SecurShield HD cover board was installed, fastened to the InsulBase insulation with HP fasteners. The final step was to roll out the Sure-Flex PVC membrane, adhering it with Carlisle’s Low-VOC Bonding Adhesive for optimal adhesion and superior wind-uplift performance, another characteristic that was essential for a rooftop that would endure Boston’s severe winter weather.

The installation of the two remaining rooftop levels with concrete decks included the same steps, with the exception of the insulation and membrane application. For the concrete deck assemblies, the installation crew chose to use Carlisle’s 8-inch SecurShield polyiso insulation, which features unique fire resistant and moisture-resistant properties while also enhancing the thermal efficiency of the building. Once these assemblies were ready for the PVC membrane, the installed it using Carlisle’s RhinoBond fastening system. The RhinoBond fastening system significantly minimized the labor and installation cost by reducing the number of fasteners needed on the rooftop by up to 50 percent. In addition, the use of this fastening system also enabled the crew to space the fasteners evenly across the rooftop, eliminating rooftop flutter and the potential for membrane blow-off.

With the PVC roofing systems in place, the Boston Celtics will be able to practice during any season, in any weather, for decades to come. The combination of PVC’s long-term durability and the detailed craftsmanship of the crew from Marshall Roofing and Sheet Metal will ensure this facility remains safe and dry through the harshest Boston winters.

TEAM

Roofing Contractor: Marshall Roofing and Sheet Metal Co., Inc., Peabody, Massachusetts, marshallroof.com

MATERIALS

Membrane: 60-mil Sure-Flex PVC, Carlisle SynTec Systems, carlislesyntec.com

Air/Vapor Barrier: VapAir Seal 725TR, Carlisle SynTec Systems

Insulation: InsulBase Polyiso, Carlisle SynTec Systems

Cover Board: SecurShield HD Cover Board, Carlisle SynTec Systems

Be the first to comment on "PVC Roof Protects the Boston Celtics at the Auerbach Center"