The Tile Roof Institute (TRI) Concrete and Clay Tile Installation Manual for Moderate Climate Regions allows for open (flashing exposed) and closed (tiles meet over flashing) valley installations. Installers develop a preference based on their experience with the local climate. Contractors also consider job-specific environmental conditions, aesthetic preferences, pitch and maintenance needs when choosing from valley-installation options.

Although there are a wide variety of flashing and installation options for valleys, one important requirement is often overlooked and can cause leaks with low-profile tile. The specification is listed on pages 48 and 49 of the installation manual: “When a flat profiled tile is installed as a ‘closed valley’, a ribbed valley metal or single crown valley metal with batten extension shall be used.”

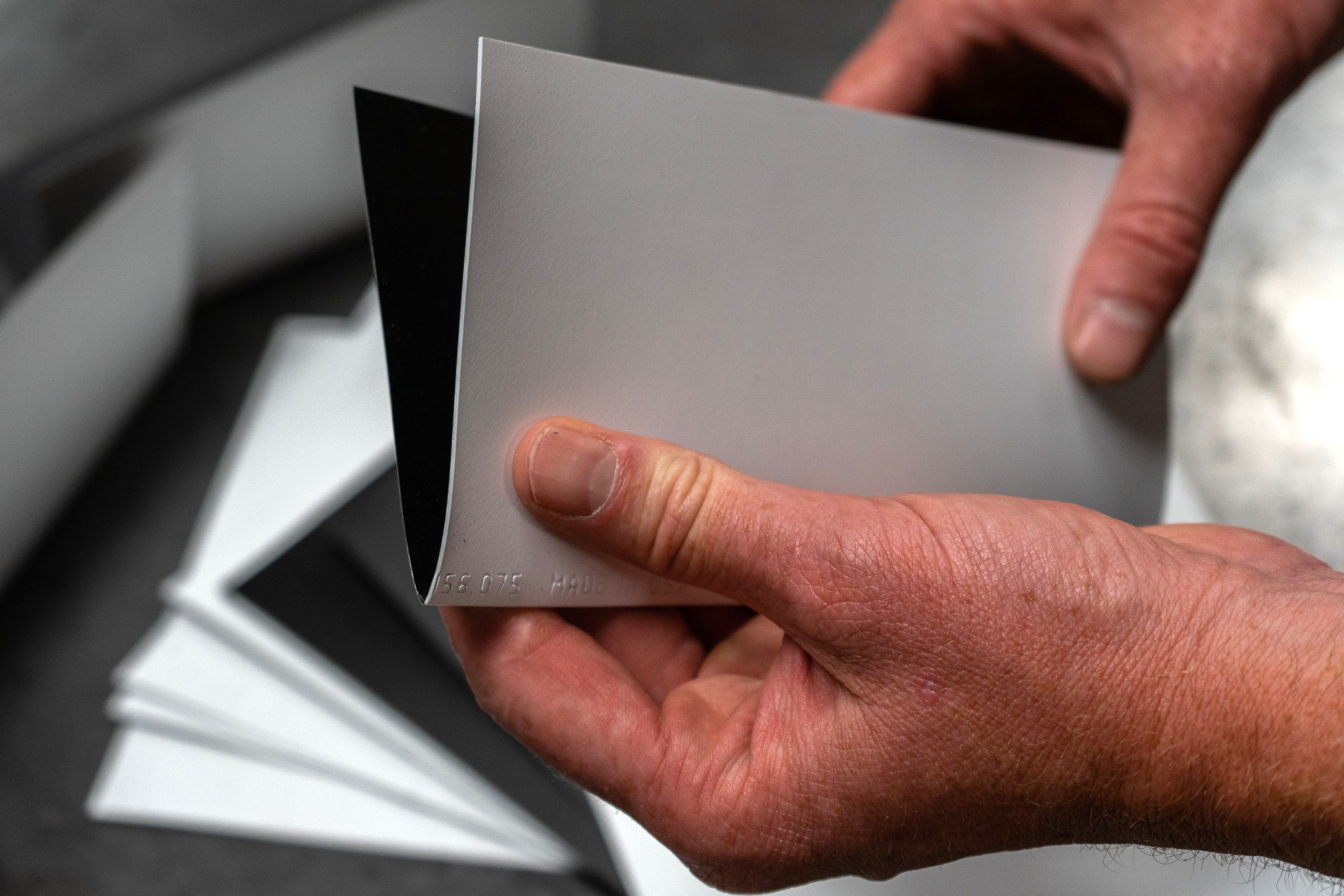

Unobstructed water flow in the valley flashing is critical. A flat tile installed directly onto standard valley flashing in a closed method restricts water in the valley flashing during heavy rains and may cause it to overflow. This can speed degradation of the underlayment and may cause rot in the battens and decking. A closed-valley installation can be repaired by replacing the standard tile valley flashing with the correct ribbed metal or by adding a batten extension to each row (see photo 1).

Because medium- and high-profile tiles have a natural cavity between the flashing and tile, this requirement only applies to low-profile tile. According to the TRI installation manual, the definition of a low-profile tile is, “Tiles, such as flat tile, that have a top surface rise of 1/2 inch or less.” Most tiles with a wood grain, lined or brushed surface still fall into the low-profile category and will require batten extensions or ribbed valley flashing.

When using a counter-batten system, or raised batten, the battens themselves can be extended into the valley because they are elevated on a pad or shim. In photo 2, a ribbed valley flashing and an elevated batten are used. Fasteners are not installed in/through the valley flashing.Tile installers are craftsmen and each develops his or her own approach to valley details. Depending on the length of the valley and the tributary area, installers may flare or gradually open the width of the valley tile cut. Experienced installers may make a cut (dog ear) to the point of the tile that is overlapped by the succeeding row. Before accessory products, like ribbed valleys and batten extensions, were commercially available and before manufacturers improved the lug design, installers often removed lugs with their hammers. They developed propping and gluing skills to avoid creating a dam with their installation. Now the accessories and flashing designs make this type of installation better and easier.

Despite the variety of tiles within the low-profile category—some are flat on the back side and fastened directly to the deck, some have lugs on the back that can also utilize battens for attachment— all low-profile tile installed in a closed-valley method requires ribbed flashing or batten extensions unless precluded by manufacturer design and/or approved by the local building inspector.

Because of Florida’s wind and weather extremes, TRI and the Florida Roofing, Sheet Metal and Air Conditioning Contractors Association collaborated on Florida High Wind Concrete and Clay Roof Tile Installation Manual, which also is available on TRI’s website.

PHOTOS: TILE ROOFING INSTITUTE, unless otherwise noted

We are having our roof replaced with Palm Beach Blend flat concrete tile. They have installed the back half already. however, we were told that there would be no visible valleys. Now, we see 2 valleys where the back tile was installed. there is no flashing evident, just the overlay white material put down to seal the roof before tiling-laymens terms. When we brought this up to our roofer, he said that they are going to leave the valley open since it will get a lot of water going down the valley and needs better water flow. The 2 in the front of the house he will close. The tile is already layed. Isn’t this an area where leaks will occur and shouldn’t these valleys have some kind of flashing layed down first before the tile?? It looks like the roofer plan forgot to plan for the valleys and now has to do a repair job on our new roof. What is your advice?

Hi Allison,

Is it fair to assume you are in Florida or the Southeast? I’m limited to the info you provided but I can share this with you- Your tile is a high profile tile (curvy) so it is not required to have the “open” valley, or special metal or batten extensions as the Low/Flat profile tile mentioned in the article must have. Valley flashing is still required. Is it possible that the valley flashing is installed under the material you see? “Open” valleys are more common in Florida due to the deluge type rains you experience. The longer the valleys, the greater the tributary area both increase the volume of water the valley must carry. I would be happy to talk with you, and can refer you to a local manufacturer’s technical representative. He’ll bring his local knowledge and product specific experience to bear for you. Please email me if I can help further. Best regards, John Jensen [email protected] 206-241-5774