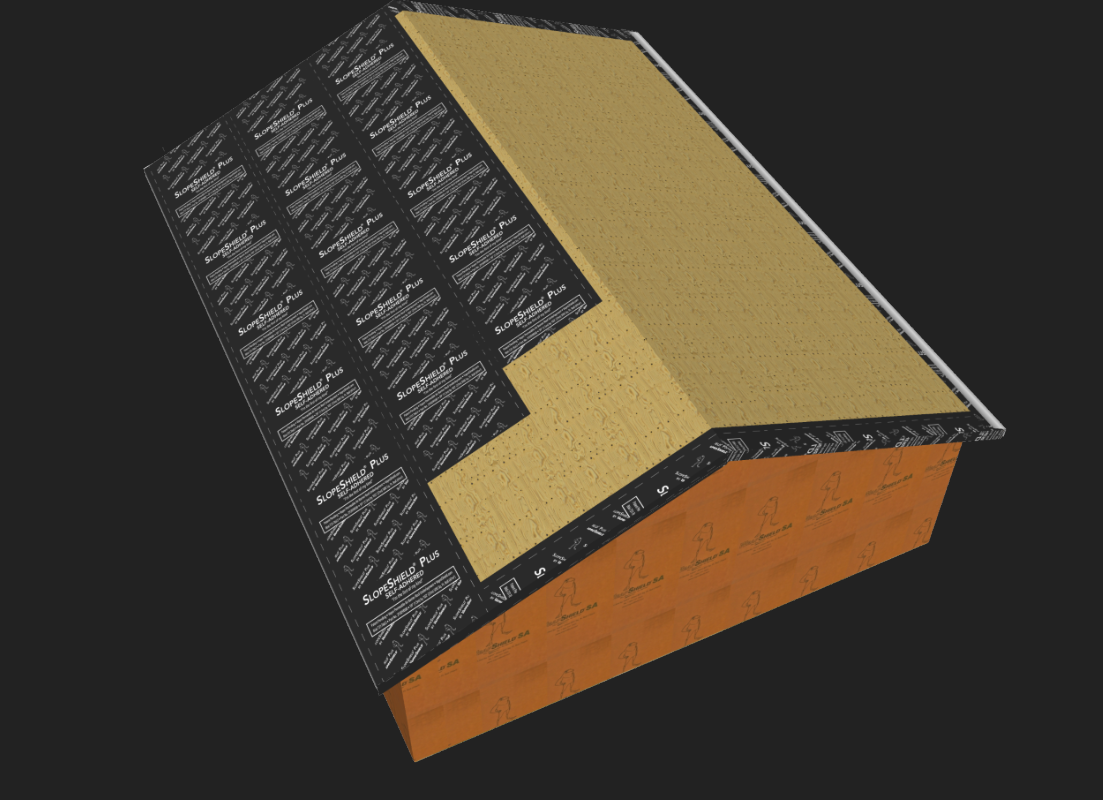

Vapor Permeable Underlayment Designed for Use on Steep-Slope Roofs

VaproShield announces the release of SlopeShield Plus Self-Adhered, a highly vapor-permeable roofing underlayment Air Barrier (AB) material. SlopeShield Plus Self-Adhered (SA), a vapor permeable roofing underlayment, is…