Expanded and Enhanced Flashing Tapes Available in New Sizes

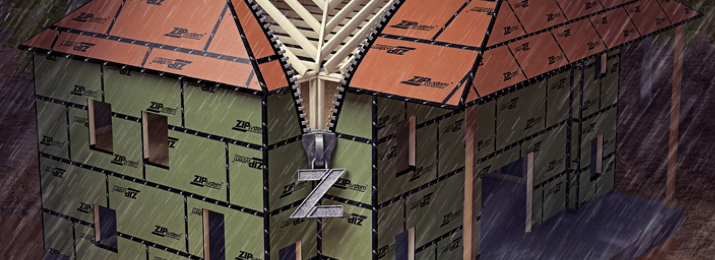

Huber Engineered Woods provides problem-solving innovations as teams and codes continue to make strides toward tighter building envelopes. A revolutionary new approach to building enclosures,…