KLA Corp. is a global technology company that develops equipment and services for the semiconductor and nano-electronics industries. Designed by SmithGroup, the company’s $200 million state-of-the-art facility in Ann Arbor, Michigan, is topped by its crowning touch — a stunning garden roof system.

To bring the architect’s vision to life, it took a talented team of construction professionals, including general contractor Barton Malow, roofing contractor CEI Michigan LLC, and green roof system supplier LiveRoof. It also took meticulous planning. As luck would have it, the companies had worked together on previous projects, so the necessary teamwork came naturally.

“LiveRoof became involved with the green roof project through the SmithGroup in Ann Arbor,” notes John Aleck, sales specialist with Nunica, Michigan-based LiveRoof. “We have teamed up with the SmithGroup on other Midwest green roof projects. LiveRoof was also very fortunate to have worked with Barton Malow as well as the CEI Michigan on other projects over the years.”

“Barton Malow Builders was the general contractor, and we have been doing business with Barton Malow for many years,” says Matt Meyer, roofing superintendent with Hamburg, Michigan-based CEI, which is a LiveRoof Certified Installer. “We were the successful bidder on the roofing scope on this project.”

The new construction project encompassed some 55,000 square feet of roof area, including the 34,150-square-foot main garden roof and two smaller green roof areas, as well as patio deck. A PVC roof system was installed on non-vegetative roof areas.

A Plan Takes Root

The plants for the green roof were grown to maturity at LiveRoof’s nursery and then labeled, loaded and shipped to the jobsite to be installed. “The patterned green roof located over the cleanroom at the facility consisted of six different sedum plant mixes based on color and growth habits,” Aleck notes. “There are two other green roofs on the building that LiveRoof also provided. One is 7,500 square feet and is located between the main building and the clean room facility. The native shade perennial mix rooftop — 2,350 square feet — is located on the employee patio located on the north side of the main building.”

Planning and coordination with CEI was crucial. “First we visited the rooftops at KLA then the CEI Michigan general superintendent came out to our growing facility in Nunica, Michigan, to consult with our production team on the best approach to layout the design and how best to coordinate the shipping to make the installation proceed smoothly,” says Aleck.

“Our biggest challenge for a grow-to-pattern green roof of this size and diversity of plant mixes was laying out the over 17,075 modules at our nursery, transporting them all to the jobsite, and ensuring their correct placement on the roof,” Aleck says. “This is not difficult provided we take a methodical approach at every step in the process. It requires discipline.”

“Everything had a home it had to go into, or you would throw your design off,” Meyer says. “LiveRoof labeled each tray. It was more work for them, but it made it much easier for us to install.”

Installation Begins

Roofing work began after the detailed, site-specific safety plan was put in place to protect everyone on the site. “As a commercial roof installer, we always have concerns about fall hazards and the best ways we can tie off our employees to keep them safe,” Meyer says. “On this project we utilized multiple means of tying off our employees including a mobile tie-off cart, permanent anchor davits, guardrails, and warning lines.”

A Carlisle 60-mil PVC roof system was installed on the high-rise office building and on two smaller ballasted roof areas. “We installed a torch-down vapor barrier on the deck,” Meyer recalls. “We installed the layers of insulation with Flexible Fast adhesive, followed by DensDeck and adhered PVC.”

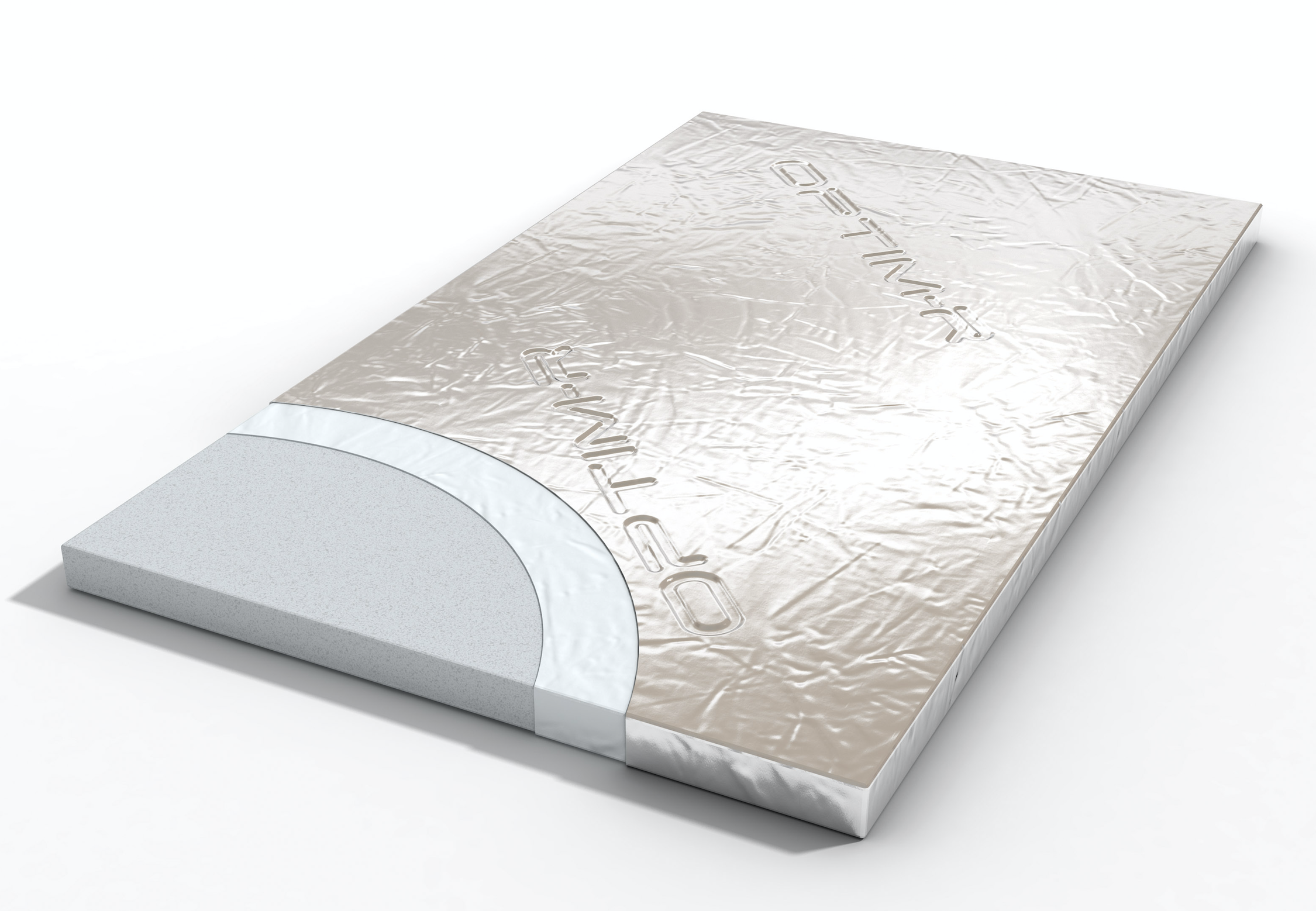

The vegetative roofs were installed over a cold-applied Laurenco waterproofing system. “The Laurenco system is applied directly to the concrete deck,” Meyer says. “You flash all of the walls with two plies of the Laurenco, and then you come back and install two plies in the field. The Laurenco roof system performs exceptionally well with water or overburden above it, which made it a great choice for this installation.”

The main garden roof was installed first. After the area was checked for leaks, the section was covered with a protection board, two layers of 3-inch GreenGuard insulation, drainage board and filter fabric in preparation for the green roof. “It’s your basic the upside-down roof system,” Meyer says. “The LiveRoof trays were installed on top of that.”

Roof Comes to Life

The pattern was then laid out on the roof and pre-grown trays were installed. The main roof also included areas where ballast was placed within the garden roof as part of the design.

“We took measurements and used utility string to lay it all out,” Meyer says. “We installed the LiveRoof trays in all of the specific areas and did the ballasted sections last. We laid out each area and fit it with metal trim, and the ballast butts up against the metal trim.”

The installation sequence began at one end of the roof, allowing the installation team to work its way off the rooftop upon completion. Equipment used during the installation included a crane to hoist the vegetative system, and ATVs, roofing carts and wheelbarrows to transport the modules across the roof.

“LiveRoof was in contact with CEI daily during the installation to make sure we had the correct section they wanted to be installing the next day loaded in the correct sequence on each of the trucks they wanted on that following day,” Aleck recalls. “This varied from two to four trucks per day. We were able to schedule them at the specific times they wanted, for a total of 26 truckloads.”

After the trays were in place, the sprinkler system and ballast were added. Large egg rock was transported to the roof by a crane and moved with wheelbarrows to specific areas. Crews worked systematically to fill in the ballasted areas without leaving tracks in the ballast or damaging the newly installed plants. “The layout of the green roof was super challenging,” Meyer notes. “You had to be spot on with it, and then you had to come back and lay ballast in those remaining areas. Everything was done by hand.”

After the main green roof was completed, work continued on the smaller, L-shaped garden roof. “We moved down below to do the second green roof, which was all one color, so it was much easier. We boomed the material over the wall with the crane and dropped it down there.”

Hanover pavers were installed on pedestals for the deck in the patio section.

Teamwork Pays Off

Aleck and Meyer credit the teamwork of every company involved in the project for its success. “We coordinated everything with LiveRoof and the general contractor in pre-installation meetings,” Meyer says. “We were just very up front at the beginning. I told the guys, ‘Once you put that roof on, there’s no adding a pipe later. Everything has to be in now. There’s no coming back.’”

“LiveRoof is a good team player, and this project demonstrates the power of a team-based approach,” Aleck says. “The design came from SmithGroup, and LiveRoof’s job was to provide the ‘living paint’ to bring their artistic creation to life. This takes horticultural know-how and a collaborative mindset. We were entrusted to recommend and grow the appropriate plants, and to exercise the discipline needed to lay out, label, and deliver the design in a manner that the installer could easily and efficiently replicate on the roof. The installer, CEI, exercised the same level of discipline, and the project went off without a hitch.”

TEAM

Architect: SmithGroup, Ann Arbor, Michigan, smithgroup.com

General Contractor: Barton Malow, Detroit, Michigan, bartonmalow.com

Roofing Contractor: CEI Michigan LLC, Hamburg, Michigan, ceigroupllc.com

MATERIALS:

Green Roof: LiveRoof, liveroof.com

Waterproofing: The Laurenco Waterproofing System, laurencowaterproofing.com

Insulation: GreenGuard XPS, Kingspan, kingspan.com

Membrane: 60-mil PVC, Carlisle SynTec Systems, carlislesyntec.com

Pavers: Hanover Architectural Products, hanoverpavers.com

Be the first to comment on "A Patterned Garden Roof Crowns KLA Corp.’s Newest Facility"