A well-known truth to roofing industry insiders is that prolonged periods of standing or ponding water pose one of the greatest threats to a low-slope roof assembly. Ponding water may shorten the service life of the roof membrane and can lead to serious problems such as water leaks, increased structural loading with potential impact to deflection of the roof deck, and life safety concerns for the occupants of the building.

It makes sense that shedding water is deemed one of the primary functions of a well-designed roof assembly. But a roof’s ability to shed or drain water effectively has less to do with the roof membrane itself and more to do with its ability to control the flow of water and direct it toward proper drainage devices. A proven solution to this challenging task, tapered roof insulation systems are a forward-thinking solution for the roofing professional, making it possible to eliminate ponding water on a membrane when the roof deck alone does not provide adequate slope or instances when the roof building structure does not accommodate positive drainage (i.e., sloped roof deck). These systems can be particularly effective in retrofit projects on existing buildings that lack proper roof slope and where achieving the desired slope through structural changes is impractical or cost prohibitive. Because tapered roof insulation systems support code-compliant water management practices, they can in turn improve the long-term performance of a roof system and extend its lifespan. The use of tapered polyiso insulation may be incorporated for optimal roof system performance.

Beyond providing positive drainage in any design or in-field condition, the thermal performance and project-by-project customization capabilities of tapered roof insulation systems have the additional benefit of providing more opportunity for roofing professionals to comply with today’s increasingly stringent energy code provisions.

What Are Tapered Roof Insulation Systems?

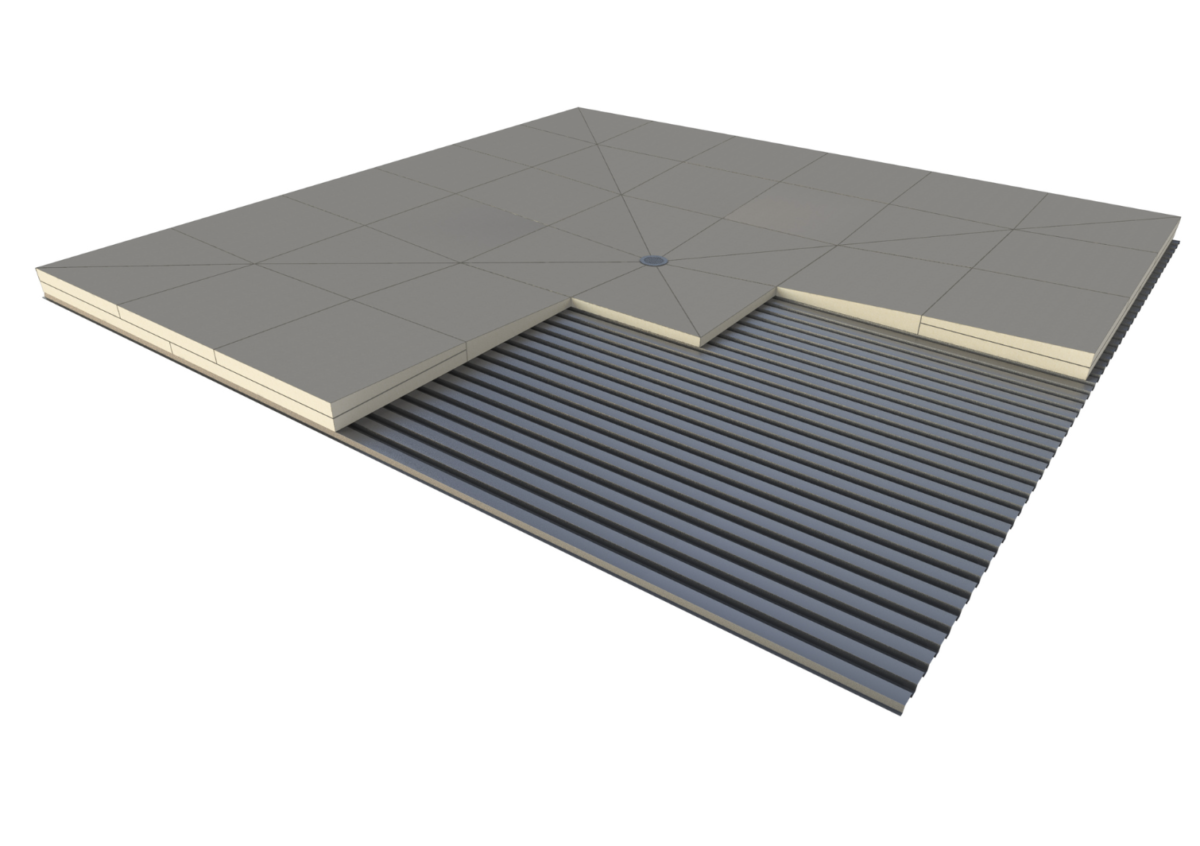

At a glance, tapered insulation systems combine tapered roof insulation with flat insulation boards and other drainage provisions (i.e., crickets) to create a multi-layered roof assembly with adequate slope. The ability to create slope in any direction makes it possible for roofing professionals to control the flow of water, directing it toward specified drainage points and, consequently, reduce or nearly eliminate the risk of ponding water.The design of each tapered insulation system is governed by the footprint and complexity of the roof, including the slope of the roof deck, configuration of primary and secondary roof drains, scuppers, and roof edge conditions (i.e., the height of parapet walls or presence of gutters or drip edges). Additionally, roof structures such as expansion joints, mechanical equipment or skylight curbs, through-wall flashings heights, window and door thresholds, and any other fixed elements that may obstruct water management also need to be considered.

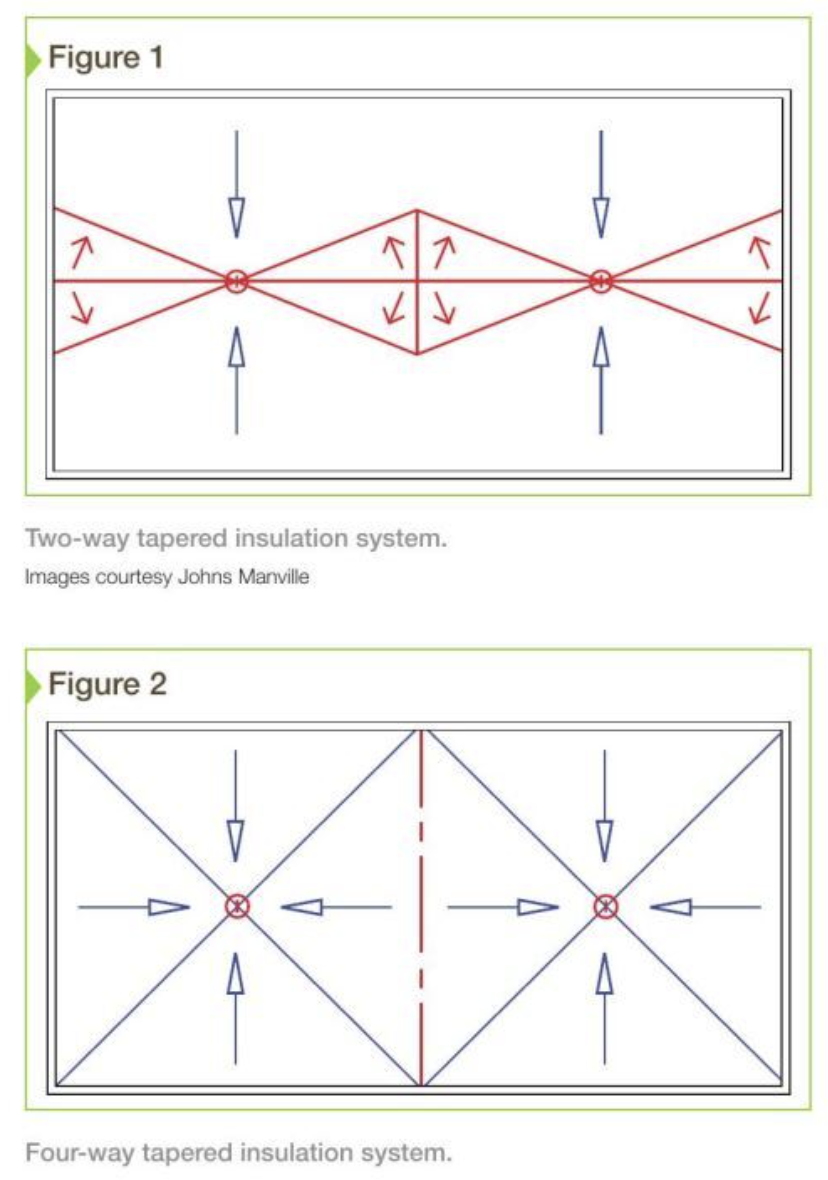

Two-way (two-directional slope) or four-way (four-directional slope) systems are the most common designs. A two-way tapered roof insulation system is typically used on roofs where multiple drains are arranged in straight lines. Tapered insulation crickets, which are frequently used in two-way tapered systems, are designed to divert water towards the drains. Low-slope roofs, however, benefit most from a four-way tapered roof insulation system. Four-way systems are typically the most efficient and effective way to manage water and ensure positive roof drainage. In this scenario, a drain is in the center, and water is drained from the higher perimeter on all four sides. Variations of two- and four-way systems do exist to accommodate complexities in the field.

Examining Building Code Requirements

According to the National Roofing Contractors Association (NRCA), adequate slope can be achieved by sloping the structural framing or deck or by designing a tapered insulation system to accommodate water drainage. A combination of the above in conjunction with the use of roof drains, scuppers and gutters may be necessary to provide adequate drainage when reroofing.

Chapters 11 and 15 of the International Building Code (IBC) contain the requirements for determining roof drainage. When tapered systems are the specified method for improving drainage, attention should also be paid to the International Energy Consideration Code’s (IECC) requirements for the opaque building thermal envelope. The IECC establishes minimum insulation requirements for commercial building roof systems with insulation entirely above the roof deck (IEAD). In application, tapered roof insulation systems contribute to design solutions that meet the energy efficiency requirements outlined in the IECC.

That said, up to and including the IECC 2018 edition, tapered roof insulation’s contribution to meeting minimum energy efficiency requirements had only been addressed in a vague manner, leaving much up to interpretation. But with the publication of the IECC 2021 edition, the requirements for calculating the R-value of tapered roof insulation systems are clear.

Section C402.2.1.1, tapered, above-deck insulation based on thickness, says where used as a component of a roof/ceiling assembly R-value calculation, the sloped roof insulation R-value contribution to that calculation shall use the average thickness in inches (mm) along with the material R-value-per-inch (per-mm) solely for R-value compliance as prescribed in Section 402.1.3. According to Section C402.2.1.2, minimum thickness, lowest point, the minimum thickness of above-deck roof insulation at its lowest point, gutter edge, roof drain or scupper, shall not be less than 1 inch (25 mm).

With these clarifying changes, building owners can more easily take advantage of the added energy performance of tapered insulation.

Achieving Long-Term Performance

Tapered insulation systems are a proven, code-compliant approach to water management, making it possible to overcome insufficient roof slope and solve complex or limiting rooftop conditions that may pose challenges in reroofing with flat stock insulation. That said, these systems can add upfront costs to a new construction or reroofing project, and may come under scrutiny during a value engineering analysis. However, forgoing a tapered insulation system can compromise the long-term performance of and ultimately reduce the lifespan of a roof assembly. In the same vein, the building owner risks trading savings on the roof assembly for increased costs over its service life resulting from poor roof drainage, including additional roof maintenance and even premature roof system failure.

Although roof assembly design, job conditions and budget constraints may vary, tapered insulation systems can add years to the performance life of any roof by sidestepping these mentioned risks. And due to its wide use in low-slope roof applications, tapered polyiso insulation systems offer numerous benefits in addition to providing positive drainage: thermal performance to meet energy code requirements, versatility, customization to accommodate project-by-project complexity, and compatibility with other roof system components.

While tapered insulation systems have an integral role in the long-term performance of the roof assembly, proper design and installation are equally as important. Every roofing project and its associated challenges are unique, so many polyiso manufacturers provide consultation, technical and education services for industry professionals involved in the design, specification and installation of code-compliant tapered roof insulation systems.

To learn more about prioritizing performance overhead, visit polyiso.org and look to the Polyisocyanurate Insulation Manufacturers Association’s Technical Bulletin #108 on tapered insulation systems.

About the author: Marcin Pazera, PhD, is the technical director for the Polyisocyanurate Insulation Manufacturers Association (PIMA). For more information, visit polyiso.org.

Be the first to comment on "Prioritizing Performance Overhead With Tapered Roof Insulation Systems"