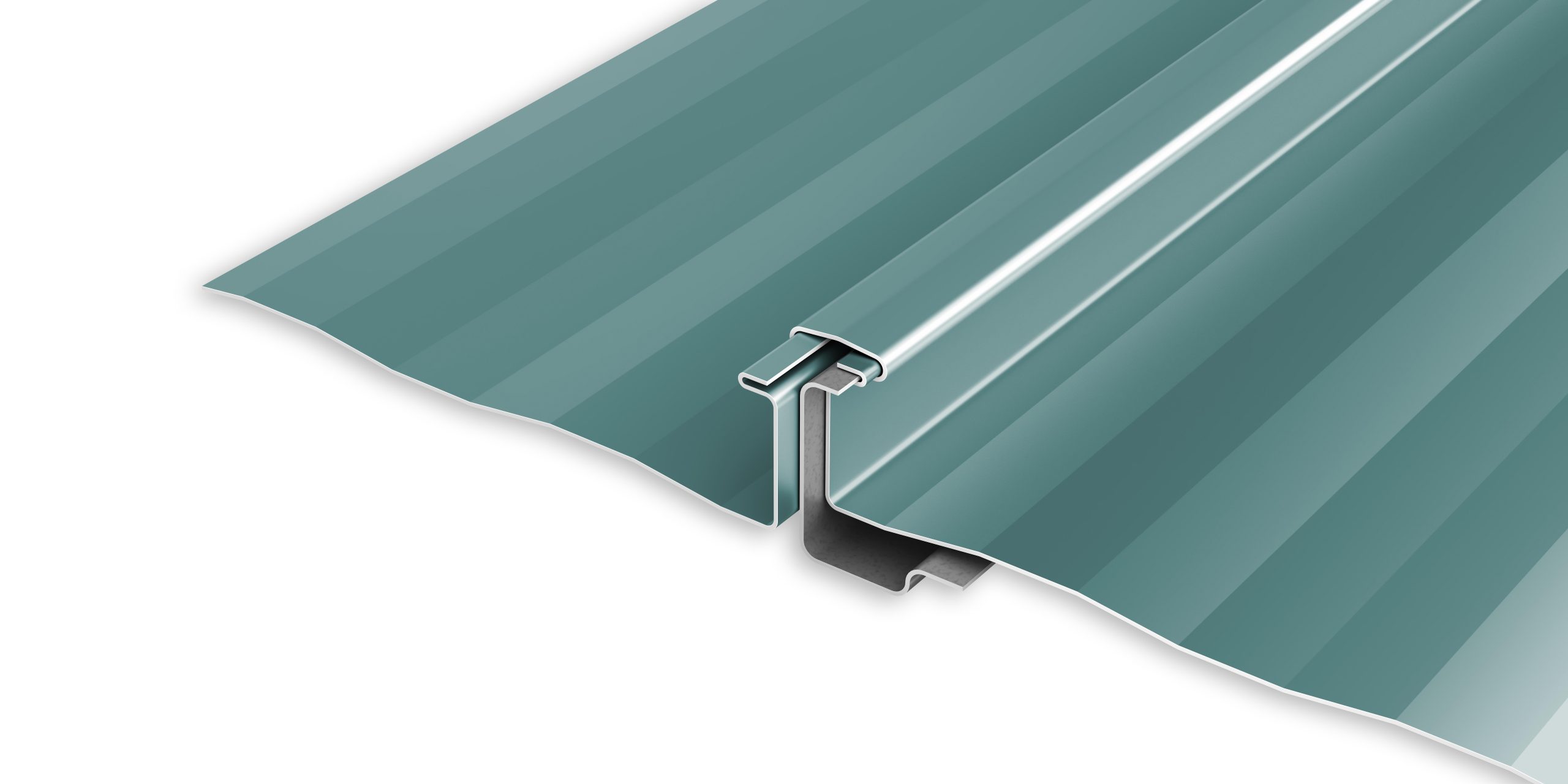

At the downslope joint, the curb flange mates over the flat plane of the roof panels. Rib caps that are furnished loose or welded integrally into the curb flange serve to terminate the panel seams. This also is accomplished with butyl tape and tube seals concealed within the joints. The downslope joint that is created typically is reinforced beneath the assembly with a backup plate or channel. The side flanges are likewise sealed to the roof panels with butyl inside the mating components. All joints are completely hydrostatic with concealed sealants.

Other substructural components may be employed to facilitate the installation; often this type of curb is furnished with board stock insulation mounted to the curb walls. Installation of all critical seals, especially those at seam interfaces, is of paramount importance, and fasteners must be to the “dry” side of sealant beads or through them. It also is important such a curb and its components are fastened together without pinning to the building structure.

The resulting assembly is free to move thermally with roof panels while sealing completely into the roof “bathtub style,” in lay terms, or in accordance with ASTM International E2140, “Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head,” in more technical terms. Diverters should be used on the upslope flange of the curb and, whenever possible, the unit should be oriented so the smallest dimension opposes the flow of water. For example, if a unit is 3 by 5 feet, the 5-foot dimension should be parallel to the slope of the roof.Frame-mounted HVAC

Heavier equipment is sometimes mounted above the roof surface on a galvanized steel frame. The frame is constructed using round pipe legs, so they can be flashed with rubber pipe flashings. These legs extend through the roof to supporting structural members. Such a mounting is stationary, meaning there will be differential movement between the frame and roof panels.

Depending on the unit’s weight, the support frame also can be mounted on seam clamps to avoid pipe penetrations through the roof. The ribs of structural metal panels are required by ASTM E1514, “Standard Specification for Structural Standing Seam Steel Roof Panel Systems,” and E1637, “Standard Specification for Structural Standing Seam Aluminum Roof Panel Systems” to support point loads of at least 200 pounds. In other words, a unit weighing 1,500 pounds and spanning across five panel seams can be mounted this way, resulting in 10 bearing points on the five seams, each supporting 150 pounds and well within the ASTM requirement.

When ducting a frame-mounted unit through the roof, it is always advisable to use the smallest hole possible. That is to say, a very large unit only may require a very small duct penetration. A small, sheet-aluminum, all-welded curb is used to waterproof the ducted hole(s) in the roof as before. But in this case, the curb need not be structural because it supports no weight but acts as a flashing only around the duct passing through the roof. The curb style is the same in all other respects.

If the unit is mounted on a stationary frame, the curb must be slightly larger than the actual duct size to allow differential thermal movement between the two. If the unit is mounted to seam clamps, this oversizing is unnecessary because the unit and curb move together in tandem.

Be the first to comment on "Rooftop Equipment Mounting and Penetrations for Low-slope Standing-seam Metal Roofs"