There are student projects, and there are student projects. And then there are the projects of Studio 804, the hands-on learning program at the University of Kansas’ School of Architecture and Design, in which graduate students design and build an entire structure in just nine months during their final year of studies for their Master of Architecture degrees.

The program was launched in 1995 by Dan Rockhill, a Distinguished Professor of Architecture at the University of Kansas. Rockhill also heads up Rockhill and Associates, a design-build firm headquartered in Lecompton, Kansas. As the founder and executive director of Studio 804, he leads students as they design and build projects that embody sustainable and energy-efficient building solutions. Studio 804 recently completed its 16th consecutive LEED Platinum project. In an exclusive interview with Roofing, Rockhill shared his insights on the origin of the program, the importance of hands-on learning, and the role of the roof system in building performance — pointing to his students’ two most recent projects as examples.

The Birth of the Program

Studio 804 can be seen as the culmination of Rockhill’s related passions — teaching, architectural design, and building. “I came here in 1980 from New York, and I wanted to be able to both practice and teach,” he recalls.

At the time, contractors in the region were reluctant to the tackle modern-style buildings Rockhill was interested in developing. “Whatever was really different, they were afraid of,” Rockhill says. “We started doing our own building because if we wanted to see the buildings come to fruition, having done the architecture, we had better produce the building.”

He was also teaching at the time. “In the mid-90s, I was teaching a graduate design studio, which is an 800-level course. In fact, the name of the course is Architecture 804. As you could probably imagine, the design studio is kind of the blessed sacrament of architectural education. Every student that comes in to study architecture starts in a design studio the first year and spends five or six years with a design studio every semester.”

One day in class, Rockhill found himself talking to his students about a project he was working on. “I was just kind of shooting the breeze with them, and said that we couldn’t get enough people to do some work for Rockhill and Associates, my business, and they said, ‘We could do that. We’d love it.’”

“So, I went out there with them, and I couldn’t believe what I saw,” Rockhill continues. “I’ve been basically teaching my whole life up to that point, and you notice enthusiasm. You notice when they are just drunk on the potency of the experience. They’d be pulling their cars up around at night with the lights on this building. It was an old schoolhouse that we put a steel roof over the top of. It was great, and you remember that type of stuff.”

He set up similar hands-on projects for his next group of students and got great feedback. “I realized I was onto something and maybe I ought to see if I could let it become part of the curriculum,” Rockhill says. “The students would start with me and know it would be a design-build experience.”

He launched Studio 804 as a not-for-profit 501(c)(3) corporation that has an affiliation agreement with the University of Kansas. “For the first 15 years of the program, we did it all in one semester,” Rockhill notes. “The students would give up their winter break and meet me in January. We wouldn’t even have a site. We’d go like hell, design, do construction documents, submit for a permit, and build the whole thing in record time.”

The program now runs over nine months, beginning in August and ending at graduation, when students hold an open house to showcase the completed projects.

“These are great kids,” says Rockhill. “I love them, and I love to have them experience what I sort of torture them with. They have the professional design side of it in the design studio experience — and I’m all for studio and design — but they are so desperate to get some real-world experience. They just love it.”

A Metal Roof, a Flat Roof

As he prepared to start a project with a new class of students this August, Rockhill looked back on his two most recent projects — residences on 432 Indiana Street and 519 Indiana Street in the historic Pinckney neighborhood in Lawrence, Kansas. Both projects have strict sustainability goals.

“Each year, we complete a house or a university-related commercial building, alternating between standing seam roof and flat roof projects,” says Rockhill. “We design modern buildings — that’s what architects do. A big thing is sustainability. These are LEED Platinum buildings. Platinum is the highest level you can achieve in terms of its sustainable qualities. Platinum means these things are performing.”

The students design and install every phase of the project, from the foundation to the roof, and everything in between. (They also do all of the exterior concrete work and even seed the lawn.) Rockhill taps into his own construction experience to direct his students. “In my business, we didn’t sub anything, so I learned how to do flat roofing, I learned how to do plaster, I learned how to do tile. So, we are a one-stop shop. We do everything.”

The most recent projects were built on vacant sites in the neighborhood. “I pick up what I call orphaned sites,” Rockhill says. “I get the sites that the builders don’t want to grab because what they would have to do goes beyond their budget. We’re able to work with these orphan sites because I can afford to make the improvements that I need to in order to make the building work.”

Donations from manufacturers in the construction industry help Studio 804 minimize costs and also expose the students to a variety of building materials and methods. “This is a feel-good story for everybody,” Rockhill states. “We get a lot of industry support, the students learn a lot, and I get out of faculty meetings to do what I do, so we’re all happy.”

432 Indiana Street

Studio 804’s most recent project, the house at 432 Indiana Street, features a standing seam metal roof on both the 1,800-square-foot home and its adjacent 500-square-foot accessory building. To help it meet LEED criteria, the roof was topped with a 16-panel solar array. Other environmentally friendly features include an exterior louver shading system, a mini-split system for heating and cooling, a hybrid hot water heater with heat pump technology, and LED lighting. The site also features a permeable driveway and a rain garden with native plants to capture storm water.

The goal on these projects is typically to get the structure framed and the roof dried in before Christmas break. In January, students return to install the finished roof system.

“In this case, we framed that roof with 2-by-12s,” Rockhill says. “We run half-inch OSB on top of that. On top of that we use nail base, 3-inch polyiso, in that case from Atlas Roofing. On top of that we run a peel-and stick underlayment that will have the ability to receive the roof material itself.”

This project incorporated Slopeshield underlayment, which was donated by Vaproshield. The metal roof panels were fabricated on site by a local supplier, Town and Country, and installed by the students. “In this case it’s a 16-inch pan, and the standing seam in this example is an inch and three quarters because I had bags and bags of leftover clips that size from a previous job,” Rockhill notes.

Working with local suppliers is a key part of the educational experience, adds Rockhill. “It’s good for students because they realize the value of the input they get from people in the industry,” he says. “These kids get to interact with people in the business who have been putting down metal roofing their whole lives.”

The students are usually doing these tasks for the first time, and Rockhill is there to oversee each phase. “I have enough experience know where the quicksand is,” he says. “I know what they might forget and not look at. I tell them that you’ll be lucky if the roof is square on each plane, and they say, ‘What are you talking about? We used a tape measure.’ And I say, ‘We’ll see.’ Sometimes they learn a hard lesson in the end.”

Rockhill provides direction, but the students do all of the work. “I tell them, ‘Everybody has a task, and you’ve got a lot of this to do, so you better figure out the most efficient way to do this,’” Rockhill explains. “Pretty soon they begin to hit a rhythm, and they go like hell. They love the kind of rush that gives you.”

Safety training is crucial. In this case, the roof’s 12:12 pitch was a challenge, and crew members would be working at height both on the roof and in the building’s interior, under the open roof. Rockhill says he tackles subjects including fall protection and ladder safety “very carefully.”

“I am always on them about the safety stuff,” he says. “Fortunately, we’ve never in all of these years had an incident. I try like hell to make sure it’s all done right.”

Solar Panels, Snow Retention

After the roof system was in place, the next steps included mounting the solar array and setting up a snow retention system. Key design considerations included the tight deadline, aesthetics, and finding maintenance-free solutions that did not penetrate the metal roof. The students chose non-penetrating systems from S-5! for both applications, installing the solar panels using the PVKIT and then the ColorGard snow retention system, which matched the color of the roof.

“I’m working with kids who don’t understand that if the water blows in through a penetration, and it drips down through the nail base product — which it will find its way in — that soaks the cellulose,” Rockhill explains. “You don’t know until the cellulose is soaked like crazy until you see a stain on the ceiling. By then, the cellulose is molding. I give them these horror stories and say, ‘I don’t want to see these things happen. You need to understand that penetrations in the roof membrane are not to be taken lightly.’ And then I talk about the S-5! clips and the value that they bring us. S-5! is sweet; I started with them years ago.”

S-5! donated the materials for the project. “The company has a great name — S-5! The students remember it, and they are going to be in an architect’s office somewhere, hopefully doing solar, and they will remember using those clips,” Rockhill says.

519 Indiana Street

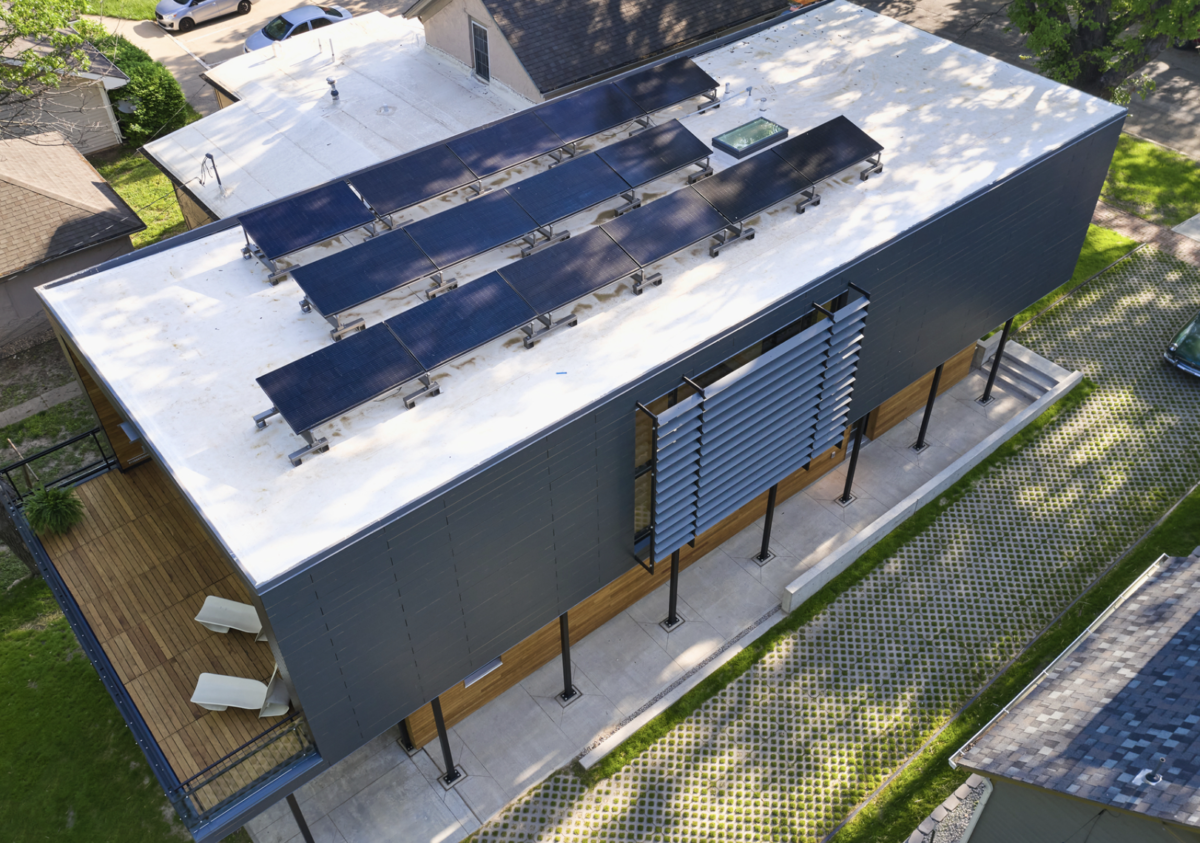

The house at 519 Indiana Street was the most recent project to feature a low-slope roof — in this case a system featuring 60-mil TPO, donated by GAF. It was topped with a 6-kW solar array.

The timing of the project makes cold weather a major concern when installing single-ply roofing, and Rockhill has found using the RhinoBond induction welding system minimizes temperature concerns.

“If you look at the schedule, we usually get it blacked in before Christmas, and we come back to put the roof on,” Rockhill explains. “So, it’s January. January in Kansas is not a pleasant month. It’s cold. We always found ourselves waiting for the right temperature range. So, when I first saw the RhinoBond, I said, ‘This is for me.’”

On this project, students cut their own tapers to provide proper drainage, installed polyiso insulation, half-inch OSB and a cover board. “Then we calculate the proper screw lengths to accommodate the tapers,” Rockhill says. “We start with the long screws and work our way down.”

“Rolling out the TPO is kind of the grand finale,” Rockhill says. “We roll out the TPO and leave enough excess on our edges to get everything nailed off per our details. And then we dial in the RhinoBond and get going.”

Details included the flashing, end caps, and gutters. “We conceal our gutters and downspouts behind the rain screen areas,” he says. “We then come out and take the downspout to a drain that is buried.”

“They are more complicated, but I love doing the flat roofs,” Rockhill says. “I’m from the old days, and the first time I ever did a flat roof, it was a built-up roof. I was up there with organic felts and a kettle and an 800-degree glass mop. I have to tell these kids when I do this stuff, ‘If you only knew what it used to be like.’ The whole industry has changed so much. It’s great to see, and I love and embrace this technology.”

Open House

The projects involve very hard work on a very tight schedule, but as the building comes together, Rockhill shares his students’ excitement. “Even standing the walls up is a thrill to them,” he says. “Gradually, as they begin to see this, they are charged. And I’m relentless in how I stay on them to help them push it through. I tell them, ‘You’ll have a lot of explaining to do when we have an open house on graduation weekend and you have to explain to the visitors why we aren’t finished.’”

The last phase of the project is preparing the presentation for the open house. At the most recent event, there were more than 1,200 visitors in one day. “The kids are proud, as they should be,” Rockhill says. “These are sophisticated buildings, and we have to be able to speak intelligently about this stuff. When my students ask about areas in which they could use improvement, I always say, ‘communication.’”

Rockhill agrees that the roof system sometimes gets short shrift in architectural study, but that’s simply due to the breadth of subjects to cover. “It’s tough,” he says. “You just can’t cover everything in depth. Even in a lecture course, students might forget half of what you’re talking about. But the hands-on thing, they never forget. Learning by doing — that’s how we should try to do this.”

The architectural curriculum can be overwhelming, but the Studio 804 experience helps drive the lessons home. “It’s not like the kid who learned to do the roofing is going to become a roofer, and he probably won’t become a builder, but with this behind them, he will be able to communicate with them very effectively,” Rockhill says. “The larger dimension is that it builds confidence. And I think once they’ve had this experience, they come out of that feeling almost cocky. They get a little bit of everything and feel so much more knowledgeable.”

An added bonus is that the experience often translates into a higher starting salary once the students enter the workforce. “The proof is there because they can ask the former grad students who are now in these jobs,” Rockhill says. “I use that to convince them because that’s the carrot they need to have in front of them — occasionally. I just remind them that if you kick ass here, you’re going to go places.”

432 Indiana Street Lawrence, Kansas

TEAM

Architect/General Contractor: Studio 804 Inc., Lawrence, Kansas, studio804.com

MATERIALS

Metal Roof Panel: 1 ¾-inch standing seam, 24-gauge, Kynar coated

Underlayment: Slopeshield, Vaproshield, vaproshield.com

Nail Base: ACFoam Nailbase, Atlas Roofing Corporation, https://www.atlasrwi.com

Solar Module: Q.Peak Duo, QCells, qcells.com

Solar Attachment: PVKIT, S-5!, s-5.com

Snow Retention: ColorGard, S-5!, s-5.com

519 Indiana Street Lawrence, Kansas

TEAM

Architect/General Contractor: Studio 804 Inc., Lawrence, Kansas, studio804.com

MATERIALS

Membrane: 60-mil TPO, GAF, gaf.com

Solar Modules: QCells, qcells.com

Insulation: EnergyShield Pro Continuous Wall Insulation, Atlas Roofing Corporation, https://www.atlasrwi.com

Be the first to comment on "Graduate Architecture Program Takes Learning by Doing to an Elite Level"